Often, we are asked to add different colour finishes to our stainless-steel lifts. A common request is to Gold Plate our Stainless Steel. Originally, we searched the web to outsource this process however we could not find anyone who could come to our workshop or directly to a client to carry out this work on site. So, we decided to gold plate our stainless steel ourselves. We are so proud of the quality of the finish our experienced engineers can achieve and knowing that there is a gap in the market, we decided to outsource this process ourselves.

All our plated finishes can be used for interior restoration, scientific and medical applications, musical instrument renovation, architectural plating, bathroom furniture, car parts, handrails, sheet stainless steel, brushed stainless steel to name but a few. The chemicals we use contain 8 grams of pure 24 carat gold per litre.

Gold is by far the most popular metal to plate using the brush plating technique and spectacular results can be obtained on a wide range of surfaces, both metal and non-metal. Gold brush plating is ideal for small batch plating, plating in situ where removing the item to be plated isn't an option (for example bath taps and door handles), very large objects that would be difficult to fit in a plating tank and selective gold plating of larger objects such as goblets and plating on to non-conductive materials such as plastic or glass.

Brush plating involves three main steps.

- Preparing the surface. Brush plating may not be able to fill in scratches, so we make sure we remove those by hand or machine polishing. After that, we clean the surface to remove any debris or residue. Finally, we may need to activate your surface if it has developed an oxide layer. Oxidation most commonly accumulates on stainless steel or nickel-containing alloys.

- Plating. We estimate the surface area of your work and acquire the appropriate amount of plating solution. Then, we use electricity from our rectifier to start plating. The rectifier’s two leads will be connected to the plating tool and the part to be plated respectively. When the tool touches the part, the circuit will be completed. The operator can control the voltage, polarity, and amperage. Brush plating requires constant motion. We can keep the tool steady and move the part or vice versa (or a combination of the two).

- Finishing. Seal your project with a sealing solution.

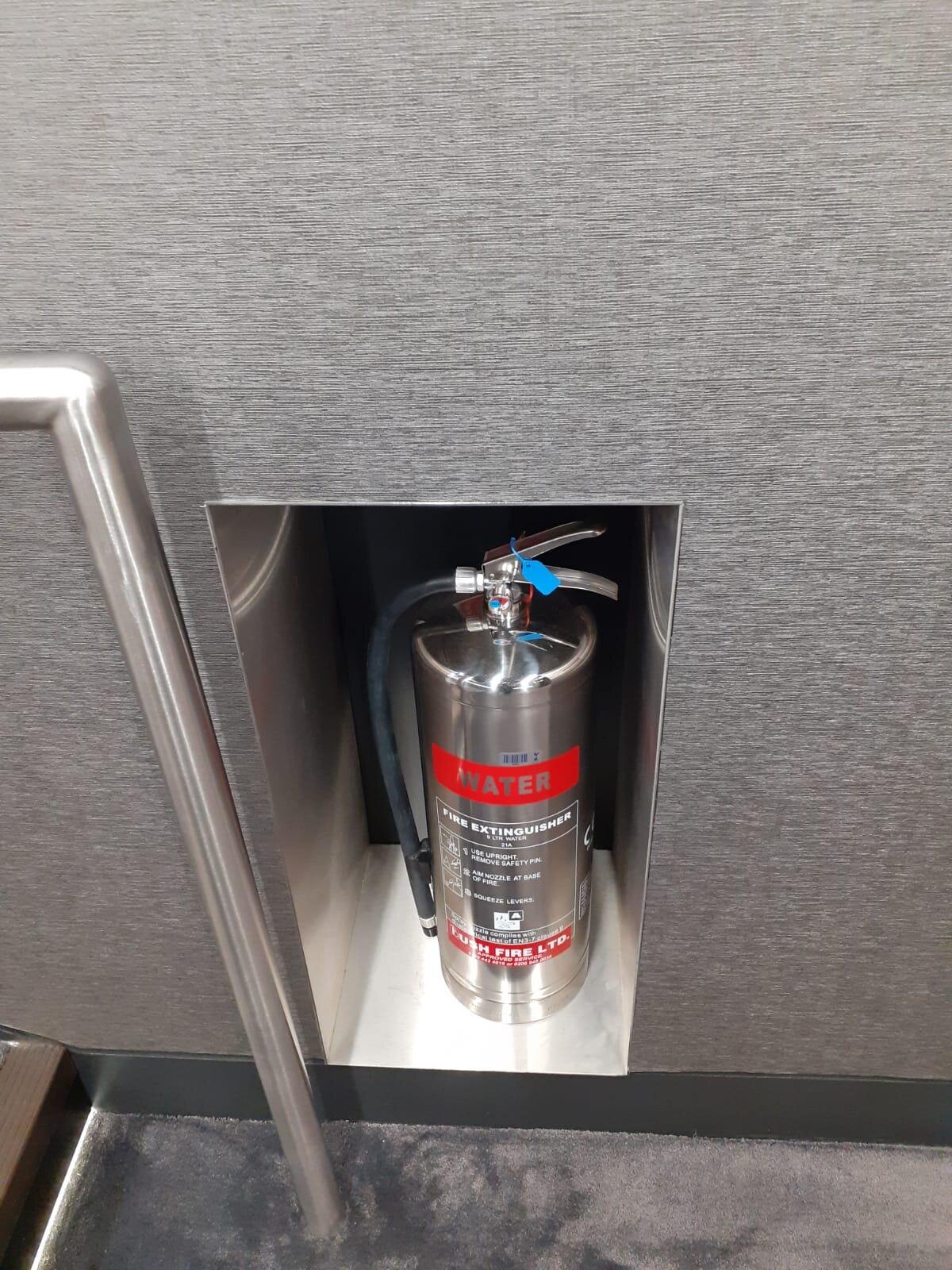

Gold plating stainless box before

Gold plating stainless box after

Contact Us

Please contact us attaching photos of the items you would like us to plate to enable us to quote. Please also add the site address.