Q&A's for Sesame Traversing Lift

Product Definition & Overview

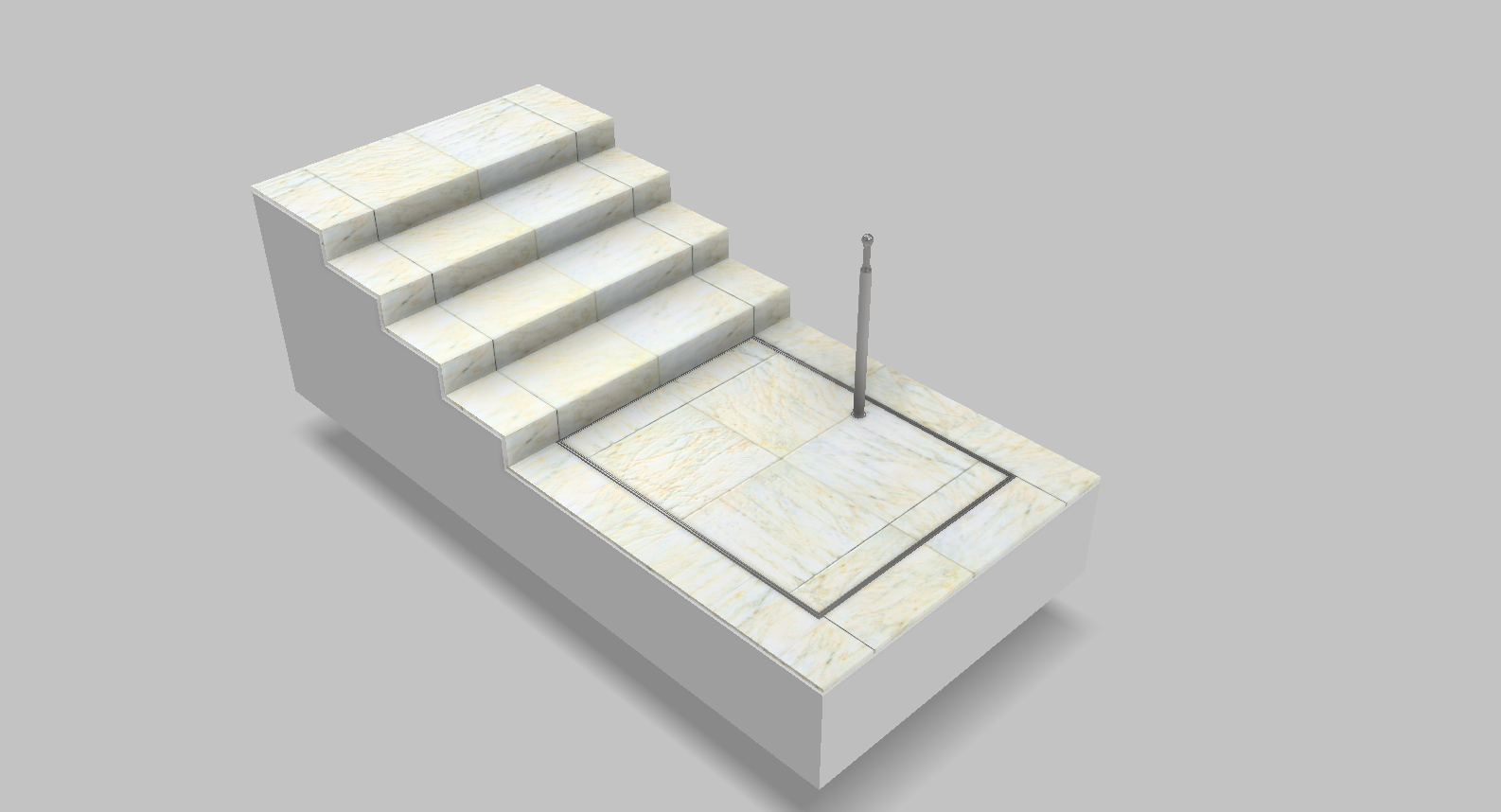

Q: What is the Sesame Traversing Lift? A: The Sesame Traversing Lift is unique in that it sits in front of the bottom step riser, rises vertically up to 660mm, and traverses horizontally up to 850mm. Unlike other Sesame systems that sit within stairs, this lift takes up space in front of the bottom step riser and doesn't require space below the stairs or upper landing.

Q: What makes the Traversing Lift different from other Sesame products? A: The key difference is that it sits in front of the bottom step riser rather than within the stairs. It's also typically cheaper than products like the Kensington, Mayfair, or Knightsbridge, and doesn't require excavation below the stairs or upper landing.

Q: Who is this lift suitable for? A: The standard version is for seated users only. Manual removable handrails (1100mm high) can be added for standing users. Permanent handrails and gates can be provided by special design with additional cost.

Technical Specifications

Q: What is the maximum rise height? A: As of October 6th, 2025, the maximum rise is 660mm.

Q: What is the maximum traversing distance? A: The lift can traverse up to 850mm horizontally (approximately three treads at just over 280mm each).

Q: What are the platform dimensions? A:

- Platform width: 1226mm

- Platform length: 1573mm

- Minimum usable space width: 1067mm

- Usable space length: 1557mm

Q: What is the minimum pit depth required? A: 310mm below lower landing finished floor level, allowing for 20mm cladding on the lift pit.

Q: What are the pit dimensions? A:

- Pit width: 1358mm

- Pit length: 1646mm (measured from the bottom step riser going forward)

Installation Requirements

Q: Can the lift be installed without modifying existing stairs? A: Yes, typically the starting point would be the existing finished clad bottom step riser, with no modifications to the stairs required.

Q: Can this lift be installed externally? A: Yes, the lift can be installed both internally and externally. External installations require appropriate drainage solutions and use galvanised mild steel or stainless steel construction.

Q: What drainage options are available for external installations? A: Three options:

- Gravity drain (preferred) - pit floor slopes to local drain connection

- Sump pit and pump inside lift pit (requires lift to be raised for engineer access)

- Separate sump chamber with surface hatch outside lift pit (preferred when gravity drainage isn't possible)

Q: What materials are used for internal vs external installations? A:

- Internal: Mild steel painted with stainless steel trims

- External: Galvanised mild steel or stainless steel

- Coastal/marine environments: Grade 316 stainless steel (rather than standard 304)

Q: What space is required in front of the bottom step riser? A: A pit measuring 1646mm long × 1358mm wide × 310mm deep is required in front of the existing bottom step riser.

Safety Features

Q: What safety features does the Traversing Lift have? A:

- 100mm tow guard that rises around the platform

- Upper landing side tow guard independently lowers to release user

- Emergency lift lower key switch

- IP-rated electric actuators for external use

- UPS battery backup system (standard)

Q: What happens if there's a power failure? A: The standard UPS battery backup system will power the lift to return it to lower landing finished floor level, allowing safe evacuation.

Q: How does the tow guard system work? A: When the lift rises, tow guards rise 100mm around the platform to prevent wheelchair wheels from rolling off. The upper landing side tow guard independently lowers when the lift reaches the top, allowing the user to exit safely.

Control Systems

Q: What control options are available? A: Three main options:

- Button station on the lift for independent control

- Removable handheld post (no buttons, just for holding)

- Remote control for trained users (allows independent use without controls on lift)

Additionally, button stations at upper and lower landings are required to call the lift.

Q: Can the lift be controlled independently? A: Yes, wheelchair users who have been given training can be provided with a remote control to independently operate the lift, or a button station can be mounted on the platform.

Q: Where can the landing button stations be mounted? A: Button stations can be:

- Wall-mounted (flush or surface)

- Mounted on pedestals

- Clamped to glass balustrades (if nearby)

Customization & Finishes

Q: Can the platform be customized with different cladding? A: Yes, any cladding thickness can be accommodated, but thicknesses greater than 20mm will require a bespoke platform and will increase the pit depth. This is considered special design.

Q: What are the standard finishes? A:

- Trims: 6mm stainless steel (brushed finish) or anodized aluminium

- Standard visible elements: Stainless steel brushed finish

- Frame: Aluminium panels (can be anodized to different colours at additional cost)

Q: Can different finishes be applied? A: Yes, options include:

- Electroplating on steel elements

- Powder coating on steel elements

- Anodized aluminium in various colours (additional cost)

Machine Room Cabinet

Q: What are the machine room cabinet dimensions? A:

- Height: 1615mm

- Width: 1144mm

- Depth: 300mm (Height is designed for engineers to work at comfortable head height)

Q: How far can the machine room cabinet be from the lift? A: Ideally within 10 metres conduit route length. Distances over 10m require specification changes to hoses and motor pump, with cost implications.

Q: What power supply is required? A: Single phase, neutral plus earth, 230V AC, 16 amp breaker for standard installations.

Q: What are the environmental requirements for the machine room cabinet? A:

- Damp-free room, preferably internal

- Ambient operating range: 0°C to 35°C

- Can be installed externally (it's waterproof)

- Requires minimum 900mm clear working space in front for electrical safety (BS 7671)

Q: What hydraulic system specifications are used? A: Standard specification:

- Motor: 1.1 kilowatt

- Displacement: 3.2 CC

- Flow rate: 4.3 litres per minute

- Hydraulic oil tank: 3.8 litres

Comparison with Other Products

Q: When would I choose a Traversing Lift over a Kensington or Mayfair? A: Choose the Traversing Lift when:

- You cannot excavate below the stairs or upper landing

- Space in front of the bottom step riser is available

- Budget is a primary concern (it's cheaper)

- Rise is 660mm or less

- Horizontal travel is 850mm or less

Q: What are the limitations compared to other Sesame products? A:

- Limited to 660mm rise (versus 500mm for Kensington, 999mm for Mayfair)

- Limited to 850mm traverse

- Requires space in front of stairs

- Standard version is for seated users only

- Takes up floor space in front of stairs when at rest

Q: If the rise is greater than 660mm, what alternatives are there? A: Consider:

- Kensington (up to 500mm, within stairs)

- Mayfair (up to to 999mm, with upper landing rising barrier)

- Westminster (up to 2999mm with standing/seated users) Contact Sesame project managers for specific requirements exceeding standard specifications.

Design & Planning

Q: What information do you need from architects? A:

- Total rise required

- Number of steps and their configuration

- Rise height of each step

- Tread depth of each step

- Available space in front of bottom step riser

- Type and thickness of cladding materials (upper landing, risers, treads, lower landing)

- Internal or external installation

- Site layout drawings (PDFs and DWGs)

- Photographs of the area

Q: Are site-specific drawings available? A: Yes, after providing your email address and confirming you're an architect, Sesame can create site-specific drawings following a detailed Teams meeting (approximately 45 minutes) to extract all necessary information.

Q: Can the lift accommodate different riser heights and tread depths? A: Yes, the lift is bespoke and can be manufactured to match your specific stair geometry, within the maximum rise and traverse limitations.

Q: How do I get started with a project? A:

- Provide your email address to receive standard drawing packs

- Review the drawings to confirm suitability

- Book a Microsoft Teams meeting with Sesame project managers

- Provide detailed drawings and site information

- Receive site-specific drawings and pricing

Q: Can Sesame help with planning applications? A: Yes, site-specific drawings can be used for planning applications. Sesame has not yet been rejected for planning.

Cost & Value

Q: Is this the most economical Sesame solution? A: Yes, the Traversing Lift is typically cheaper than the Kensington, Mayfair, or Knightsbridge options, particularly when space below stairs is unavailable or difficult to excavate.

Q: What factors affect the cost? A:

- Platform size modifications

- Cladding thickness beyond 20mm

- Addition of permanent handrails or gates

- Special design requirements

- Machine room cabinet distance from lift (if over 10m)

- Custom finishes (anodizing, powder coating, electroplating)

Compliance & Certification

Q: What standards does the lift comply with? A: The lift complies with relevant British Standards BS 6440:2011 for platform lifts and is certified to Machinery Directive requirements.

Q: Is the lift suitable for disabled access compliance? A: Yes, the lift provides accessible routes for wheelchair users and, with additional handrails, can accommodate standing users as well.

Maintenance & Operation

Q: How is the lift maintained? A: Engineers can access the lift pit when it's in the raised position. The machine room cabinet houses all electrical and hydraulic systems for easy maintenance access.

Q: What happens during a power failure? A: The UPS battery backup automatically powers the lift to return it safely to lower landing level.

Q: How long does installation take? A: Installation timescales vary by project. Contact Sesame project managers for specific timelines based on your project requirements.

Q: What training is required for users? A: Wheelchair users who will operate the lift independently with a remote control require training on safe operation and the requirement to return the lift to lower landing position after use.

Q: How often does the lift require servicing? A: Contact Sesame for specific maintenance schedules. External installations may require more frequent inspection of drainage systems.

Next Steps

Q: How do I receive drawing packs and pricing? A: Provide your email address to confirm you're an architect or qualified client. Sesame will then share relevant drawing packs and pricing information.

Q: Can I arrange a consultation? A: Yes, Microsoft Teams meetings can be arranged with Sesame project managers to discuss your specific project requirements in detail.

Q: Where can I find more information? A: Visit sesameaccess.com or contact the Sesame project team directly through the website.

Note: Specifications current as of October 6th, 2025. Product development continues, so contact Sesame for the latest specifications and options.