The horizontal retracting stairs

Horizontal Retracting Stairs - Technical Specification

Overview

Horizontal retracting stairs are a key component of several Sesame Access platform lift systems. When activated, the stairs retract horizontally below the upper landing level to reveal a platform lift underneath. This design allows the lift to remain concealed when not in use, preserving the aesthetic appearance of traditional staircases.

Applicable Products:

- Kensington Stairlift

- Mayfair Stairlift

- Regent Stairlift

- Knightsbridge Stairlift

- Westminster Stairlift

- Whitehall DDA Lift

- Cambridge Part M Lift

- Paddington Stairlift

- Oxford Disability Lift

How Horizontal Retracting Stairs Work

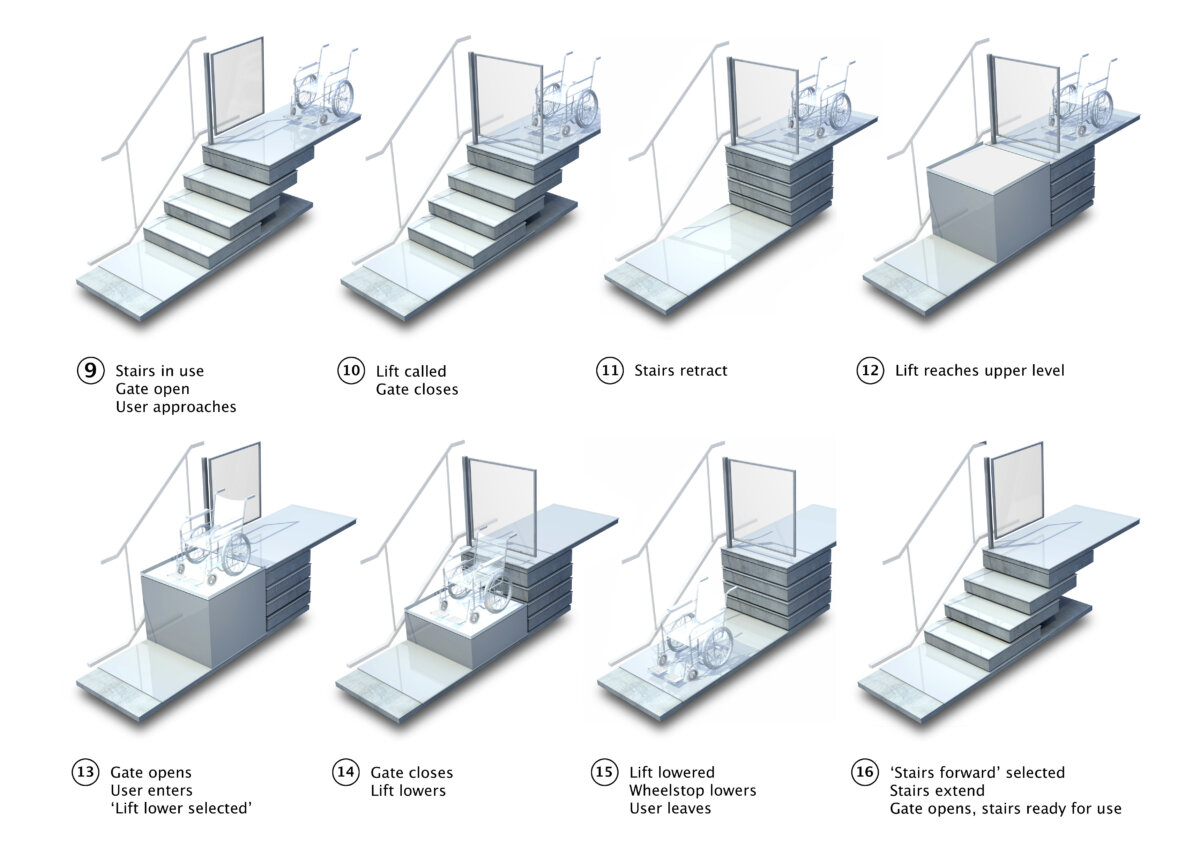

Operation Sequence

- At Rest Position: Stairs are extended, presenting as a conventional staircase

- Activation: User initiates lift operation via button station or remote control

- Barrier Rises (if applicable): Upper landing barrier or gate activates first

- Stair Retraction: Stairs retract horizontally into a pit below upper landing level

- Platform Revealed: Platform lift is exposed and ready for use

- After Use: Process reverses - platform lowers, stairs extend, barriers lower

Actuation Systems

Standard Hydraulic System:

- Single-acting RAM (most economical for shorter runs)

- Double-acting RAM (for longer extensions or restricted pit space)

- Hydraulic cylinders controlled via machine room cabinet

Electric System (Big Bend product only):

- Electric actuators

- Requires significantly less horizontal pit space

- Higher cost but suitable when space is severely constrained

Pit Space Requirements for Retracting Stairs

Standard Dimensions

Optimal Configuration:

- Distance from top step riser to back of stair pit: 1200mm

- This dimension accommodates single-acting RAM (most cost-effective)

Absolute Minimum:

- Distance from top step riser to back of stair pit: 800mm

- Below this requires special design or alternative products

Calculation Formula

The pit length can be reduced proportionally based on actual stair extension:

Formula:

For every 2mm reduction in stair extension (E),

you can reduce pit length by 1mm

Where E = horizontal distance the bottom step riser travels from the top step riser

Examples:

| Stair Extension (E) | Minimum Pit Length (Top Riser to Back Wall) |

|---|---|

| 1555mm (standard) | 1200mm |

| 1000mm | 922.5mm |

| 900mm | 872mm (but still use 800mm minimum) |

| 700mm or less | 1200mm (can use cheaper single-acting RAM) |

Pit Depth Below Stair Mechanism

The horizontal stair pit shares the same depth as the platform lift pit in most standard installations.

Standard Approach:

- Main contractor forms one continuous pit at a single level

- Platform lift sits at the required depth (see Pit Depth Calculations)

- Retracting stair mechanism sits on a packing frame to bring it level with platform

Minimum Depth for Stair Mechanism:

- Typically 150mm below upper landing finish floor level

- Can be reduced by special design if necessary

- Consult project managers for pit depths less than 150mm

Width of Horizontal Stair Pit

The stair pit width matches the platform lift pit width.

Standard Width Calculation:

For a platform with 1000mm usable space:

| Configuration | Total Pit Width |

|---|---|

| Standard with removable handheld post | 1132mm |

| With side-mounted button station | 1186mm |

Upper Landing Stair Pit Components

Service Hatches

Purpose: Provide access to the stair mechanism and platform lift for maintenance

Configuration:

- 2-3 service hatches at upper landing level

- Number depends on weight of upper landing finish material

- Hatches are clad in the same material as upper landing floor

Access Methods:

- Via service hatches from above

- Via engineer's override key switch to raise platform beyond upper landing level, allowing access from below with safety bars in place

Rising Barrier Systems (Product-Dependent)

Some products require an upper landing barrier or gate:

Products with Rising Barriers:

- Mayfair (telescopic rising barrier)

- Westminster (three independent rising barriers)

- Knightsbridge (rising barrier + rising button post)

- Whitehall DDA (rising barrier + platform hand rails)

- Paddington (U-shaped rising barrier)

Barrier Pit Depth:

- Minimum 1600mm below upper landing finish floor level

- Separate pit cut-out required specifically for barrier mechanism

- Independent from the main platform lift pit depth

See detailed specifications: On Lift Rising Barriers

Horizontal Retracting Stairs – Additional FAQs

How do Sesame horizontal retracting stairs operate?

The stairs extend over the lift platform when the system is at rest and retract horizontally beneath the upper landing when the lift is activated. Once the lift cycle is complete, the stairs extend again to return the staircase to its normal appearance. This design allows full accessibility without altering the surrounding architecture.

How far do the stairs retract under the landing?

The distance from the top step riser to the back of the stair pit is typically 1,200 mm. This provides the most efficient motion and the lowest stress on the mechanism. In restricted spaces, the minimum possible retraction distance is around 800 mm, achieved with a special design.

Can the retraction distance be adjusted?

Yes. The pit length and the stair travel are linked. As a guide, every 2 mm reduction in stair extension reduces the pit length by approximately 1 mm. This means the system can be tuned for tighter spaces while maintaining safe geometry for the treads and risers.

What mechanism moves the horizontal stairs?

Most Sesame systems use hydraulic rams to retract the stairs horizontally. A single-acting ram is used in standard systems, while a double-acting ram is fitted where greater extension or restricted pit space is required. Some bespoke products, such as the Big Ben lift, use electric actuators that require less pit space.

Can the horizontal stairs be used externally?

Yes. For outdoor installations, the stair mechanism is built in galvanised or stainless steel and designed to operate in damp conditions. Proper drainage must be provided beneath the stairs, either by gravity drain or via a sump pit with pump, to prevent water damage to the mechanism.

Do the stairs share the same pit as the lift platform?

In most installations the horizontal stairs and lift platform are housed within a single continuous pit. This simplifies construction and alignment. The stair pack sits above the platform space, retracting horizontally into the same footprint beneath the upper landing.

What is the minimum staircase width for horizontal retracting stairs?

The minimum width is approximately 900 mm. This allows the stair pack and side guides to operate safely. If the staircase is narrower than 900 mm, a different lift design such as a vertical-rising platform may be required.

Can the stairs have bull nosing?

No. Bull-nosed treads cannot be used on Sesame retracting stairs because the curved nosing would become a crush hazard when the stairs retract. All treads must be square to the risers.

How is maintenance access provided to the horizontal stair mechanism?

Engineers can access the stair mechanism through two or three service hatches located at the upper landing. The lift can also be raised and locked on safety bars using an engineer override key, providing clear and safe access for inspection beneath the stairs.

Which Sesame products use horizontal retracting stairs?

The horizontal stair mechanism is used in several Sesame products including the Kensington, Mayfair, Westminster, Knightsbridge, Whitehall, Cambridge Part M, Oxford and Paddington systems. Each combines the same retracting stair motion with different upper-landing barriers or gate options depending on site requirements and user type.

Request Technical Drawings

To receive product-specific technical drawings and specifications:

- Contact our team: Provide your architectural firm details

- Verification: We verify you are a registered architect/specifier

- Drawing pack delivery: CAD files (DWG) and PDFs provided via email

What you'll receive:

- Plan views and sections

- Pit dimension requirements

- Electrical supply specifications

- Loading requirements

- Installation clearances

Need Assistance?

Our technical team can help you:

- Select the appropriate product for your project

- Calculate pit dimensions for your specific configuration

- Provide bespoke design for non-standard installations

- Arrange site surveys and feasibility assessments

Book a Microsoft Teams consultation: Schedule Technical Meeting →

This technical specification is for guidance only. All installations must be designed specifically for the project requirements. Sesame Access Limited reserves the right to modify specifications as products are developed. Consult our technical team for project-specific details.

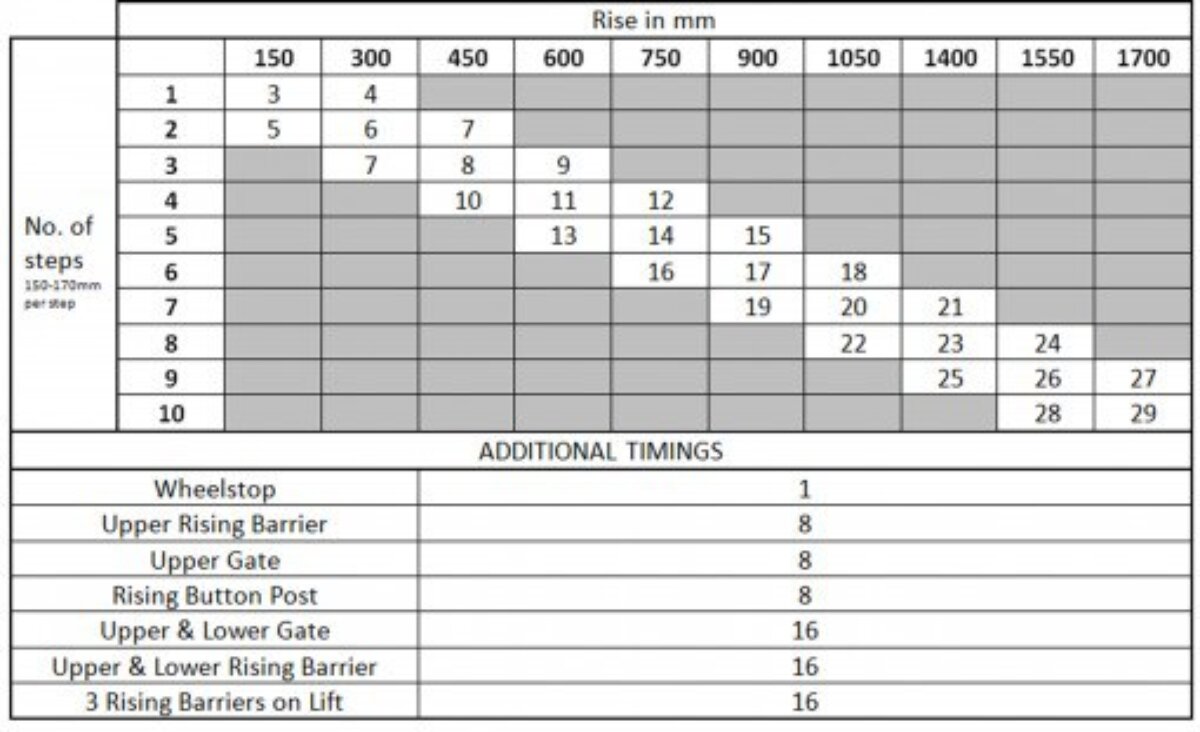

Horizontally retracting stairs will disappear into the void behind your staircase. For no more than six steps, we require a minimum of 1200 mm space. This area tends to be underneath the front door of the property so we need to check that the space is available. For more than five steps please see our equation below:

Length of stair pit = ((Total tread depth from top step riser to bottom step riser – 1555)/2)+1200 minimum total = 1200 mm.

It is also possible to consider vertically retracting stairs. For this option please talk to our team for help in deciding.

The vertically retracting stair lifts do not require a void behind the staircase as they retract down rather than sideways.

The minimum width of a staircase needs to be 900 mm wide to accommodate a Sesame lift. This is to ensure that the usable space on the platform is sufficient. The standard size for one of our platform lifts is 1000 mm wide by 1400 mm deep which is much preferable to the minimum size.

The Sesame stairs can not accommodate bull nosing as when the stairs retract and the lift rises the bull nosing becomes a crush hazard. The treads must be square to the risers.

Any nosing fitted must not protrude above or in front of the tread or riser respectively by more than 1.5 mm

The stairs can be clad in any material. The thickness of the material depends on the riser heights (typically 40 mm build on the risers and treads is a maximum).

The steps are driven hydraulically and are supported and contained within a mild steel framework. The steps are manufactured from stainless steel and are designed to accept the specified cladding type and thickness. Each riser height is adjustable independently from 120 mm to 170 mm. Each moving step is rated at 125kg of cladding. Each stationary step is rated at 240kg SWL.

The width of the staircase can be specified by the client however Crush hazards surrounding the disabled lift usually define the exact width of the staircase.