Sesame Access hidden wheelchair lifts are installed in some of the most important buildings in the world. From One Great George Street, where a bride trusted her entire wedding entrance to a Sesame lift, to national museums, embassies, and global heritage sites, these lifts are expected to work flawlessly every single time.

Reliability isn’t a marketing claim for Sesame Access – it is a culture, a process, and a continuous engineering discipline built up over 30 years of making bespoke lifts designed for real-world environments.

This article explains why Sesame lifts achieve industry-leading uptime figures, including the most recent 99.7% uptime performance, and why architects, estate managers, and contractors consistently describe Sesame Access as one of the most reliable lift engineering companies in the world.

So why are Sesame lifts so reliable?

1. Engineering decisions that eliminate the common causes of failure

Sean McAllen, Sesame’s Service Manager, joined the company in 2016 with a background in Industrial Engineering in Canada’s Aviation and Engineering Industries.

-

Sean began analysing historic call-outs, and a decade later, he manages the statistical data showing how Sesame has cut faults and boosted uptime year after year.

-

One major reliability improvement involved replacing sensitive switches on barriers and gates with modern sensors and better-controlled mechanical components. This eliminated an entire class of faults caused by environmental changes.

-

Similarly, upgrading from the old cable-and-spring stair position system to alternative-based detection created predictable, consistent behaviour across all sites.

Every engineering improvement, no matter how small, is permanently integrated into future lifts, meaning the 2025 generation is significantly more robust than the 2015 generation.

2. Over-specification and rock-solid mechanical design

Sesame lifts don’t wobble, flex under load, or make unnecessary noise because:

-

Scissor mechanisms, support structures, and drive systems are deliberately over-engineered.

-

Lifts are built far above minimum requirements for load capacity, torsional stability, and fatigue life.

-

Over-specification reduces mechanical stresses, prevents premature wear, and ensures smooth operation even in harsh environments.

Components not manufactured in-house are carefully selected, tested, and customised by suppliers specifically for Sesame applications. Supplier collaboration ensures full control over lift reliability.

3. Continuous improvement at every stage

Sesame operates like a modern engineering firm, even though every lift is bespoke. Systems protecting reliability include:

-

Full design quality control by the Head Engineer

-

Independent manufacturing quality audits for every lift

-

Independent commissioning by a different engineer

-

Delay Destroyer process to feed workshop learnings back into design

-

Call-out analysis data fed upstream to design and manufacturing

-

6 Sigma-style continuous improvement led by Sean

Because lifts are designed, built, tested, and serviced in-house at Surrey, every discovery is fed straight back into the process. If an issue is identified on Monday, checklists and procedures are updated by Tuesday.

Result: constantly evolving, increasingly reliable lifts.

4. Highly trained engineers empowered to act fast

Sesame engineers are trained through:

-

In-house training programs

-

Continuous technical development has been built over 30 years

-

Mentoring programs where junior engineers learn from experienced staff

If a lift requires service, trained engineers often attend the same or next day, following a structured diagnostic process that eliminates guesswork.

Sesame also supports apprenticeships with Nottingham University, combining hands-on experience with degree-level learning. The workforce is young, skilled, and growing, and mistakes are openly shared to improve reliability across the fleet.

5. Responsiveness across the UK and beyond

For lifts installed far from London, Sesame ensures reliability through:

-

Rapid travel (often next-day arrival, even in Scotland)

-

Remote monitoring to pre-diagnose faults

-

In-person training of trusted regional partners

-

Clear, documented handover processes

Whether in Westminster or Australia, Sesame lifts perform consistently. Remote monitoring is expanding to improve diagnostic speed even further.

6. Cold-weather reliability and outdoor performance

Outdoor and extreme-weather installations are common, and Sesame lifts are built to withstand:

-

Rain, freezing temperatures, and wind

-

High-IP-rated controls and buttons

-

Hydraulic systems designed for extreme cold

-

Weather-resistant materials

-

Non-pressure-based sensing technology

-

Custom regional adaptations (e.g., Arctic climates)

Performance has been confirmed down to -5°C, with research underway for -40°C Canadian installations.

7. A nimble, fast-acting company culture

As a small, agile British engineering company, Sesame benefits from:

-

Instant decision-making without corporate hierarchy delays

-

Engineers escalating issues directly to the Head Engineer or Design Team

-

Real-time communication between purchasing, engineering, service, and design

This internal structure ensures that fixes, improvements, and innovations happen quickly and collaboratively, keeping lifts reliable long after installation.

8. Industry-leading uptime: 99.7% and rising

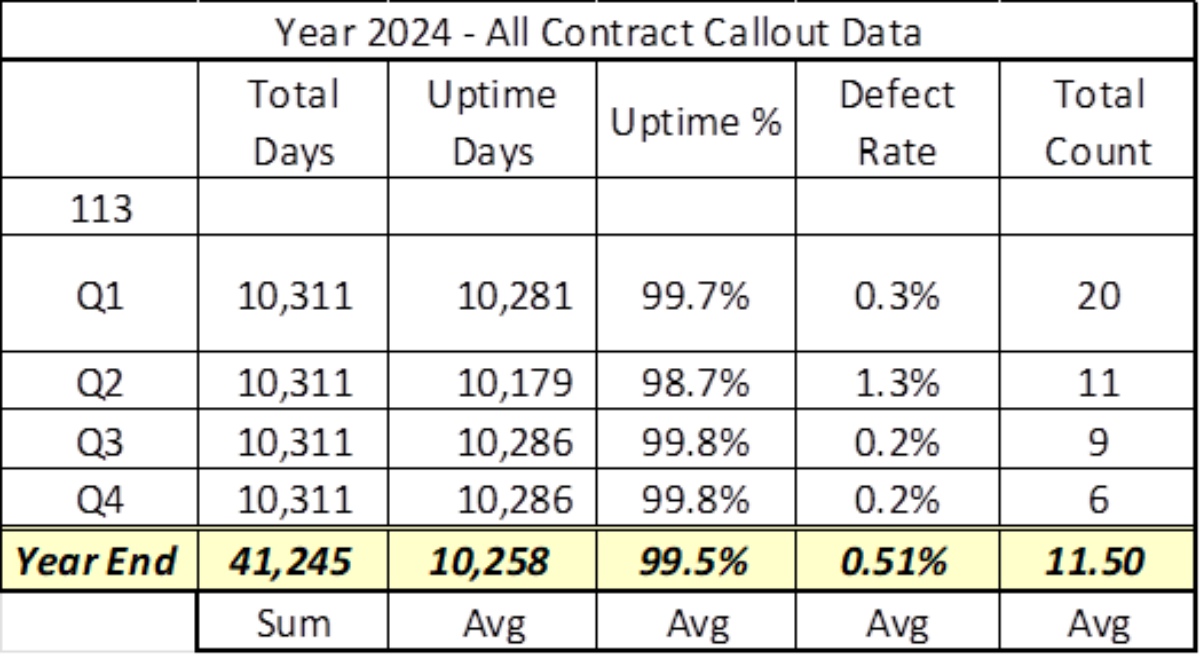

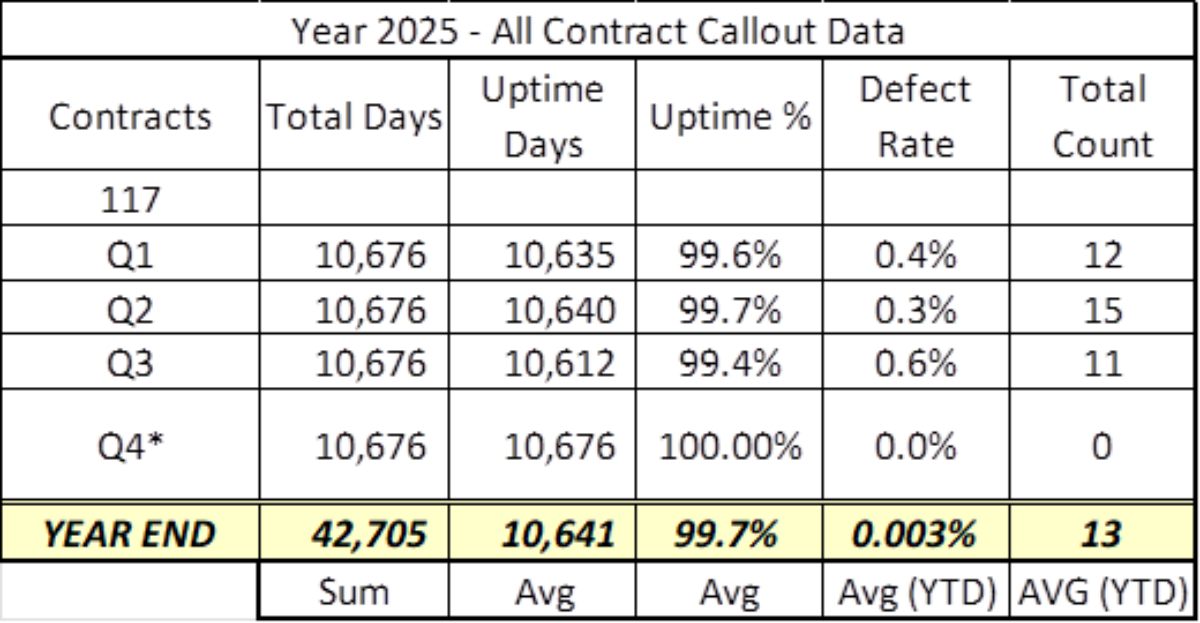

Sesame’s reliability is tracked, audited, and reported:

-

99.7% uptime in 2025

-

99.5% uptime in 2024

-

Some quarters are achieving 100% uptime forecasts

Independent consultants confirm this performance is significantly above industry standards.

Sesame Access is reliable because the entire company is built around reliability:

-

Over-engineered mechanical structures

-

Modern sensing technology

-

Fast call-out response

-

Rigorous quality control

-

Continuous improvement and transparent culture

Every Sesame lift is bespoke, benefiting from decades of engineering iteration and real-world lessons. They are designed for heritage buildings, international projects, and once-in-a-lifetime events.

One of the strongest examples of reliability is the lift at One Great George Street. On Nina’s wedding day, two lifts at the Institution of Civil Engineers transported her and four guests who used wheelchairs into and out of the venue. Every moment mattered and the Sesame lift performed perfectly.