Key Takeaways

-

Sesame Access refined its internal communication through the Legacy BOM process.

-

Structured meetings and consistent data tracking now ensure accurate, efficient lift production.

-

The workflow supports precision, transparency, and continuous improvement across departments.

Introduction

Delivering bespoke accessibility lifts demands a close partnership between design, engineering, and procurement teams. Sesame Access has strengthened this collaboration through the structured Legacy BOM (Bill of Materials) process, a workflow that aligns 3D modelling, drawing control, and purchasing to create one consistent source of truth across departments.

Primary Workflow Benefits:

-

Reduces rework and human error

-

Improves handover between design and procurement

-

Provides faster, more reliable data for manufacturing

-

Ensures version control and accountability

What Is the Legacy BOM and Why It Matters

The Legacy BOM is the backbone of Sesame Access’s design-to-production system. It connects the 3D model, detailed drawings, and purchasing data into a single validated record. Each project begins with a fully quality-checked 3D model, followed by the drawings and finalised BOM before release.

This ensures that the procurement team receives a verified list of components ready for quotation and order. By locking the 3D model before drawings are released, the process prevents late-stage design changes and helps maintain build precision

Improving Collaboration and Accountability Across Teams

Weekly Legacy BOM meetings now bring together designers, engineers, and procurement to discuss feedback and review project data. The team follows a defined cycle that includes:

-

Reviewing and signing off 3D models before drawings are issued

-

Capturing changes through structured “firework” alerts for visibility

-

Discussing priorities calmly to prevent unnecessary rework

-

Logging estimated time impacts to protect project schedules

This structured communication loop allows teams to share progress transparently while maintaining engineering discipline and time efficiency.

Integrating Design Change Management for Continuous Improvement

Every change identified during the design or build stage now feeds back into Sesame’s internal knowledge systems. When a refinement proves successful, it is logged into the parts library so future lifts automatically benefit from it.

For example, improvements applied to the Kensington Stairlift and Richmond Rising Platform Lift now inform new models from the outset. This creates a live, evolving design environment where each completed lift makes the next one better.

As part of Sesame’s commitment to continuous improvement, the integration of design change management now works hand in hand with emerging technologies — as explored in our article on Digital Validation and AI in Lift Engineering.

How Version Control Prevents Human Error

In complex lift builds, small adjustments can affect multiple assemblies. The refined process introduces clear revision tracking in Asana so every change automatically alerts the right team member.

Whether the update involves a paint finish, material substitution, or assembly component, it is approved, logged, and timestamped.

As one project engineer summarised during a review:

“When a change happens, the right person knows instantly — that’s how we prevent errors before they happen.”

Faster Delivery Without Compromising Quality

The alignment of design and procurement has shortened lead times across bespoke projects. From modern architectural spaces using the Wellington Lift to compact heritage environments featuring the Mayfair Stairlift, the new process ensures every lift is built from validated, traceable data — improving both speed and consistency across the workshop

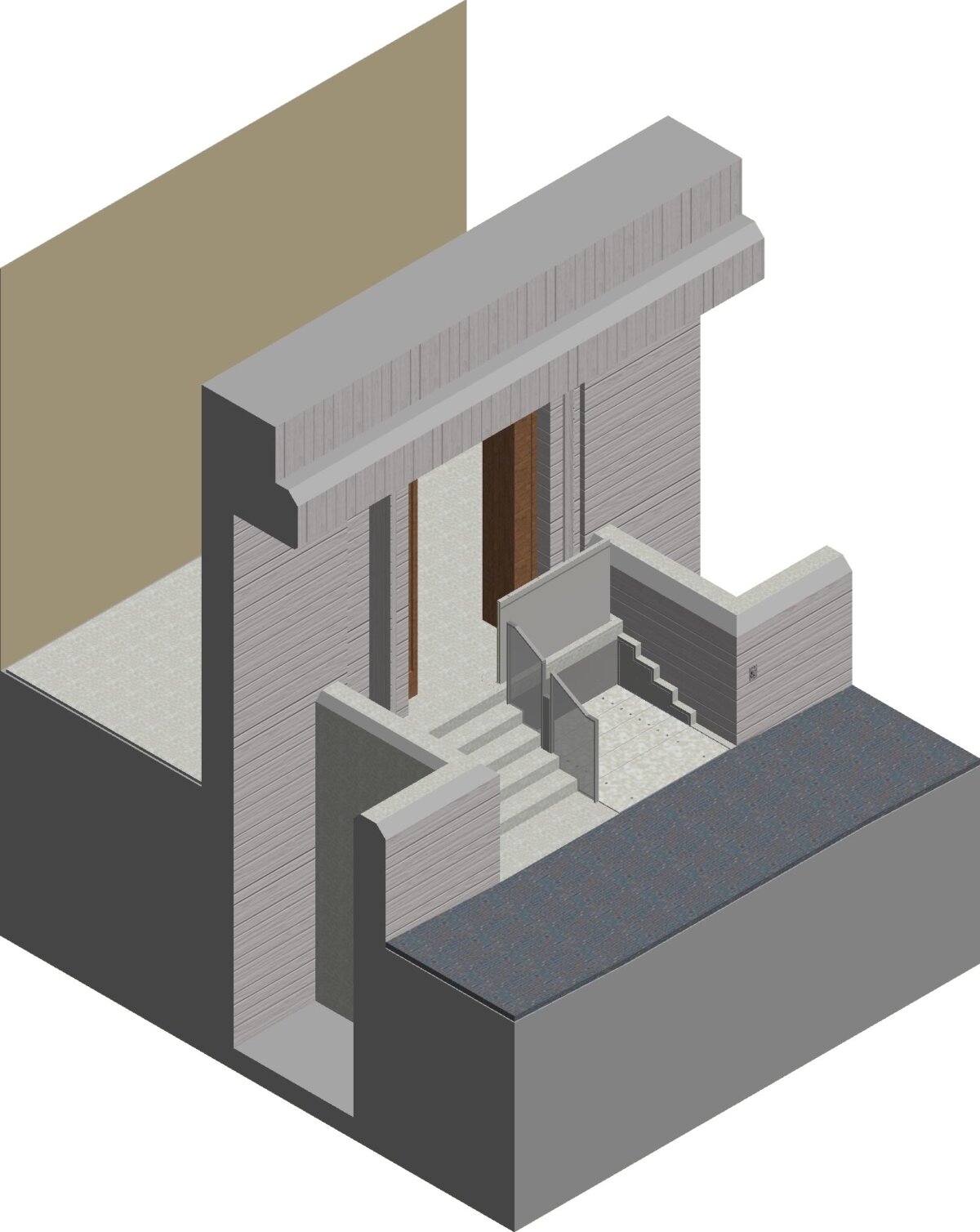

Legacy BOM 22.10.25

.

Frequently Asked Questions

What does BOM mean in lift engineering?

BOM stands for Bill of Materials — the list of parts and quantities needed to manufacture a lift.

How does version control improve build accuracy?

Version control ensures that every department works from the same drawing revision, preventing mismatched components or outdated specifications.

How often is the Legacy BOM reviewed?

The engineering team reviews and refines the process every two weeks as part of its continuous improvement schedule.

Where can I learn more about Sesame’s design review system?

You can learn more about how Sesame applies advanced digital tools within its design review system in our feature on Digital Validation and AI in Lift Engineering.

Call to Action

To learn how Sesame Access engineers bespoke platform lifts for complex architectural environments,

book a Teams meeting with one of our Project Managers:

https://www.sesameaccess.com/book-a-meeting