Key Takeaways

-

Strengthening cybersecurity in a lift engineering company is most effective when starting with low-cost, practical actions before adopting advanced external systems.

-

Simple steps like device updates, domain protection, structured internal access, and weekend offline backups significantly reduce risk.

-

Consistent cybersecurity processes protect the engineering drawings and digital assets required to deliver bespoke hidden lift systems such as the Wellington Lift.

-

Reviewing the organisation’s privacy policy and international partnership processes improves data governance and supports global operations.

-

Internal controls build resilience and reduce costs, while external IT partners can be added later for deeper system hardening.

Introduction

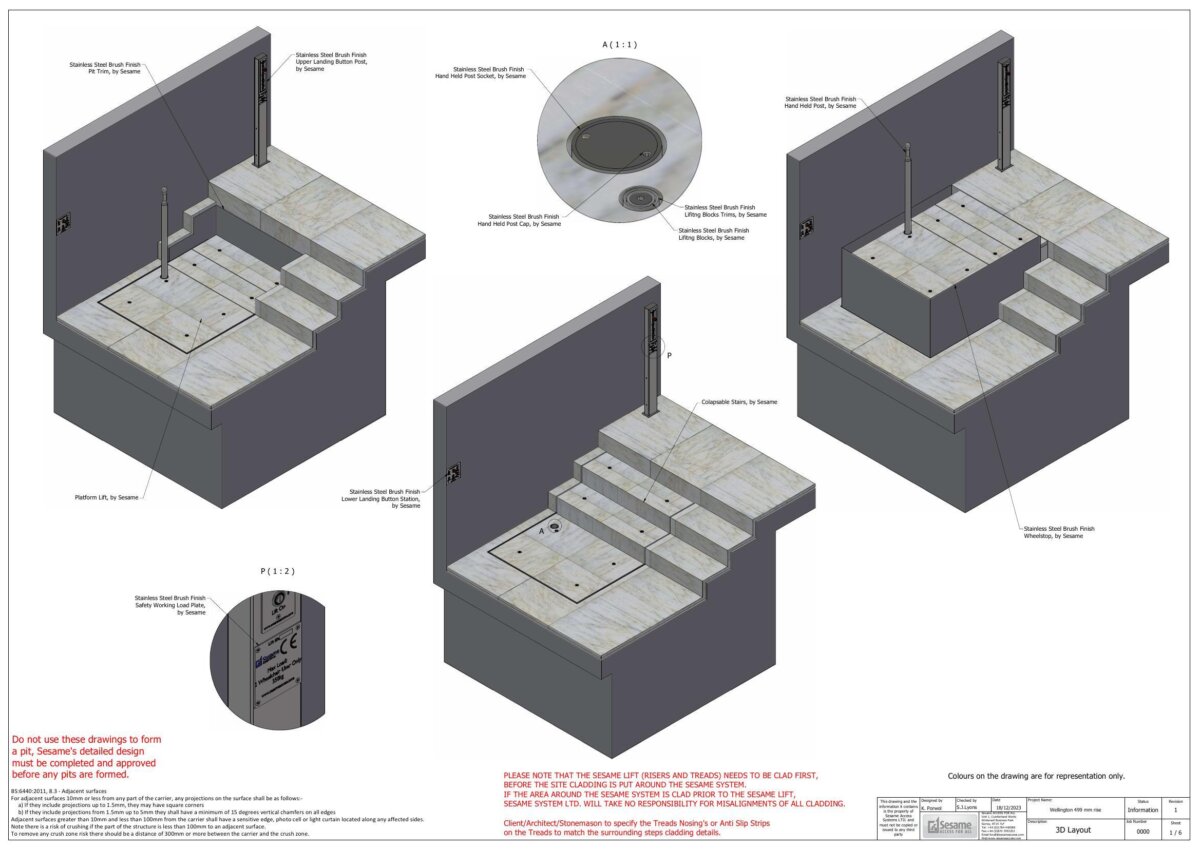

Cybersecurity protects the intellectual property, engineering drawings, PLC logic, and project documentation that drive complex hidden platform lift installations. For companies delivering bespoke systems like the Wellington Lift, cybersecurity is not only an IT requirement — it is fundamental to project delivery, continuity, and long-term compliance.

This article summarises the outcomes of an internal cybersecurity discussion and translates them into a clear, non-technical roadmap that any engineering, design, or management team can follow.

Two key resources support this topic:

-

The company’s privacy policy

-

The Knowledge Hub article on Hidden Platform Lift Partnerships: Turkey & Germany, which highlights how secure data handling supports international collaboration

Why Cybersecurity Matters for Bespoke Lift Engineering

Every bespoke platform lift generates a digital footprint of CAD drawings, tolerance documents, confidential correspondence, project schedules, and commissioning data. If these files become inaccessible, corrupted, or stolen, projects can stall and create delays on site.

This is especially critical for hidden lift systems, where millimetre-level precision is essential. Any loss or alteration of engineering assets directly affects installation quality.

Cybersecurity therefore protects:

-

Business continuity

-

Engineering accuracy

-

Compliance with architectural standards

-

Long-term client support

-

The reputation of Sesame Access as a specialist in hidden platform lifts

What Are the Most Common Cybersecurity Risks?

Human Error

The internal meeting highlighted that staff behaviour, not technical hacking, presents the greatest risk. Examples include out-of-date software, weak passwords, and accidental oversharing of folders.

Unrestricted Folder Access

Allowing every team member to access every project file increases the risk of accidental deletion, misuse, or exposure.

Unprotected Domains

Domain protection settings were found to be inactive on certain URLs. This exposes the organisation to domain hijacking or impersonation.

Unstructured Backup Practices

While cloud services provide strong redundancy, relying on them exclusively can be risky. Without a controlled offline backup, full business recovery becomes harder during major outages.

Case Study: How Internal Cybersecurity Prevented a Costly Project Delay

A recent hidden lift project (anonymised) relied on a large set of engineering files, tolerance reports, and PLC updates. An attempted phishing attack targeted one staff member’s login, which could have compromised cloud storage.

However, the following internal controls prevented escalation:

-

Multi-factor authentication was active

-

Folder access was restricted, so the compromised account lacked rights to engineering archives

-

The most recent weekend offline backup was available

The project continued without delay, and no files were lost. This practical example demonstrates why even simple safeguards can protect multi-month engineering programmes.

What Internal Actions Should Be Taken First?

1. Regular Device Updates

Keeping Windows, browsers, and software (e.g., TeamViewer) updated closes vulnerabilities immediately.

2. Structured Folder Access

Set access permissions per department. Engineering, project management, finance, and marketing should only access the folders they need.

This approach aligns with Knowledge Hub best practice outlined in the Legacy BOM Process Improvement article.

3. Domain Protection

Activate domain-level protection features and consolidate multiple domains under a single registrar to simplify security.

4. Password Hygiene

Require staff to use multi-factor authentication and secure password managers.

5. Controlled Weekend Offline Backups

A dedicated offline backup device kept outside the main office reduces the risk of ransomware, hardware failure, and cloud compromise.

This protects critical files for lifts such as the Wellington Lift, which depend on fully accurate engineering and manufacturing documents.

Comparison Table

Internal Actions vs External Support

| Internal, Low-Cost Actions | External Cybersecurity Services |

|---|---|

| Device updates | Azure security configuration |

| Access restriction | Single Sign-On implementation |

| Domain protection | Advanced threat detection |

| Offline weekly backup | Full governance and compliance frameworks |

| MFA + password manager | External penetration testing |

Before vs After Implementing Internal Controls

| Before | After |

|---|---|

| Outdated software | Regular automated updates |

| Broad folder access | Department-based access policies |

| No domain protection | Full domain security enabled |

| No offline backup | Weekly encrypted offline backup routine |

| Inconsistent password rules | Mandatory MFA and password manager usage |

Linking Cybersecurity to International Workflows

When working on cross-border hidden lift partnerships — such as those described in the Hidden Platform Lift Partnerships: Turkey & Germany article — secure file exchange becomes even more important. International partners rely on accurate, uncompromised technical documentation and consistent data governance.

Cybersecurity supports:

-

Secure long-distance engineering collaboration

-

Compliance with regional data rules

-

Stable communication channels during time-critical project phases

Key Recommendations

-

Restrict project file access to only those who require it.

-

Enable full domain protection for all registered domains.

-

Use MFA and a password manager consistently across the company.

-

Maintain a weekly offline backup located outside the main office.

-

Review and update the organisation’s privacy policy regularly.

-

Cross-check cybersecurity processes when entering international partnerships.

-

Consider external cybersecurity auditing once internal controls are stable.

Frequently Asked Questions (FAQ)

Why does cybersecurity matter if the company hasn’t been hacked before?

Because cybersecurity functions like insurance — the goal is to prevent the first incident, not recover from it.

Is cloud storage secure enough by itself?

Cloud services offer good protection, but an offline backup adds resilience against account compromise or cloud outages.

How often should backups be completed?

A weekly encrypted offline backup provides a strong balance between protection and operational efficiency.

Who should have access to engineering documentation?

Only the departments working directly on those deliverables. Access should be based strictly on role requirements.

Does cybersecurity impact hidden lift installations?

Yes. Digital accuracy affects physical installation quality. Protecting engineering data ensures lifts like the Wellington Lift install correctly and meet architectural standards.

Speak to a Project Manager

To discuss secure project setup or data handling for bespoke hidden platform lifts, you can book a meeting with our team:

https://www.sesameaccess.com/book-a-meeting