Why a bespoke hidden lift was required (this enquiry)

In this enquiry, the design team needed to make a historic entrance Budapestt accessible where a conventional ramp was impossible due to space and heritage constraints. At concept stage, a hidden platform lift with retracting stairs (Sesame “Wellington” configuration, similar to a recent reference scheme) was accepted in principle alongside an outline budget. The client has now asked the team to progress to design development and construction documentation, with procurement to follow.

Compliance route agreed (standards and certification in this case)

Because this is an open, concealed platform lift (not an enclosed lift in a shaft and not an inclined stairlift), the European lift standards EN 81-41 (vertical lifts in shafts) and EN 81-40 (inclined lifts) do not apply to this product type. In this case, the agreed route is:

-

Design basis: Sesame experience under BS 6440:2011 for vertical platform lifts (informative for geometry, guarding and use cases).

-

EU legal compliance: Machinery Directive Annex VIII (self-certification) with full risk assessment and a CE Declaration of Conformity issued on completion.

-

Local approvals in Hungary: No design-stage permit is required for this category; instead, an operational permit is applied for after installation, typically by the main contractor or specialist, with CE paperwork supporting approval.

This MD Annex VIII pathway is the same approach Sesame uses across mainland Europe for bespoke concealed platforms where no harmonised EN standard fits the exact product type.

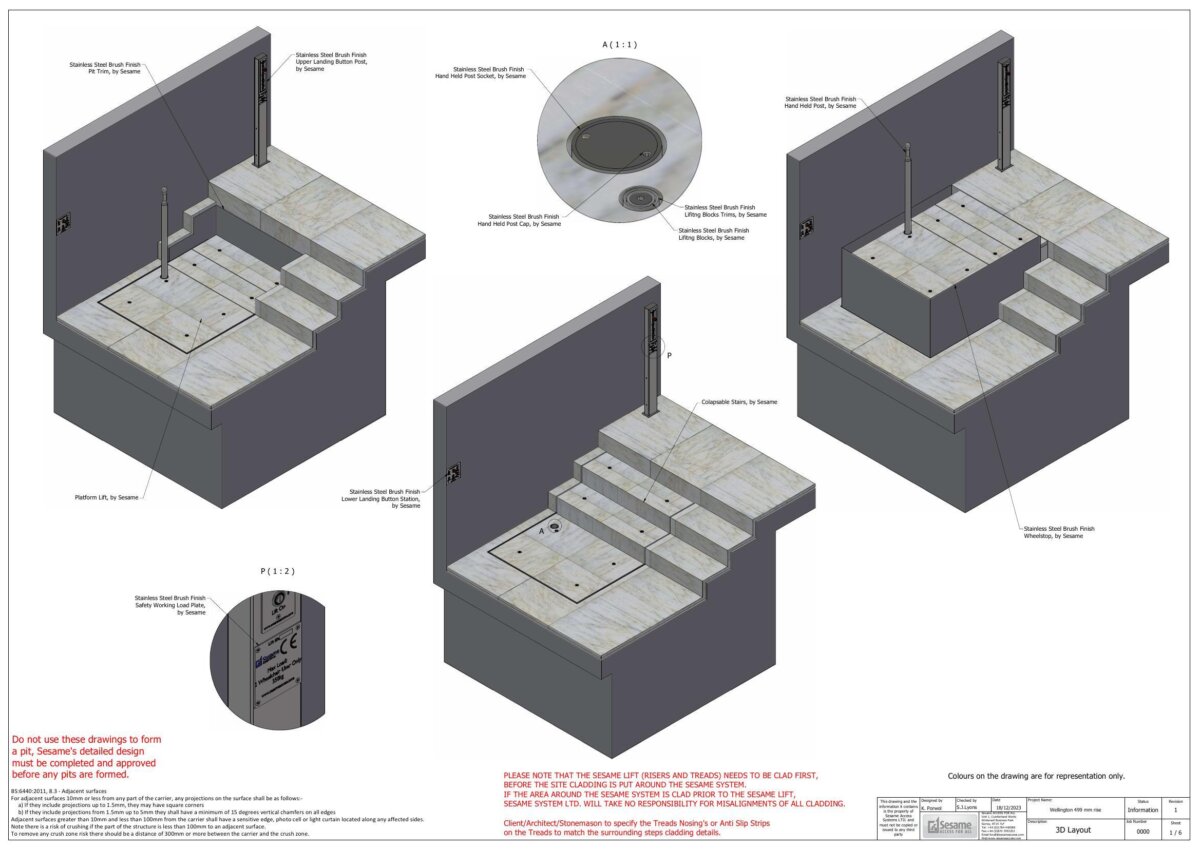

Lift type and reference: A hidden platform lift with retracting treads (Wellington-style). Reference product:

https://www.sesameaccess.com/lifts/wellington-lift

General concealed lifts overview:

https://www.sesameaccess.com/lifts

Pit geometry & structural interface:

-

Preliminary coordination indicates a service/pit zone beneath the staircase, set back approximately ~1.5 m from the bottom riser to the rear of pit (subject to detailed survey).

-

The architect will form a rectangular service space below, trimming a basement wall/vault locally and adding a retaining/partition wall as required.

-

Sesame requested rear access from the basement side via a removable access panel to simplify routine maintenance and training of local service engineers.

Relevant servicing/export page:

https://www.sesameaccess.com/knowledge-hub/export-logistics-bespoke-lifts

Waterproofing & drainage strategy:

-

The pit will take water; therefore drainage is mandatory. Final details (linear drain/sump, waterproofing interfaces at pit walls and slab, and isolation from heritage fabric) will be coordinated in the construction details package.

Pit depth / drainage reference article:

https://www.sesameaccess.com/knowledge-hub/bespoke-lift-pit-depth-solutions

Surveys & information exchange:

-

Architect holds DWG survey data for the entrance and basement; once the exact lift position is locked, a more detailed local survey of the basement vault will be undertaken.

-

Sesame offered to attend site in Budapest for a measured survey during detailed design.

Programme and deliverables (this enquiry’s timeline)

-

Now → End Oct / Early Nov 2025: Sesame to issue preliminary drawings (free of charge) aligned to the architect’s CD set—showing pit limits, access panel position, service zones, and outline interfaces.

-

By Early Dec 2025: Architect aims to complete construction documentation.

-

Procurement (post-CD): Client/PM anticipates ~2–3 months to appoint the main contractor.

-

Construction start: End Q1 / early Q2 2026 (est.).

-

Completion: Targeting end of 2026 (est.).

-

Sesame lead-in: Allow ~7 months for a bespoke lift from detailed design sign-off → manufacture → delivery. Moving quickly to chargeable detailed design compresses the overall timeline, because manufacture follows immediately after the approved design set.

Roles and scope split proposed

-

Preliminary stage (now): Sesame issues a top-level prelim pack to support the architect’s CD.

-

Detailed design: Either (A) the architect engages Sesame directly now and includes fees in their scope, or (B) the detailed design is included in the construction phase budget and placed via the main contractor. Sesame advised option (A) for schedule certainty.

-

Training & maintenance: Sesame will train a local service provider; rear access panel improves serviceability.

Servicing/export logistics reference:

https://www.sesameaccess.com/knowledge-hub/export-logistics-bespoke-lifts

Why this case matters (wider significance)

This project shows how heritage constraints, tight urban geometry, and EU permitting can be reconciled with a bespoke, concealed platform lift. The MD Annex VIII route gives clear compliance, the drainage + access panel thinking improves lifecycle maintainability, and the programme logic ensures the lift arrives in step with the broader works. For architects and project managers, it’s a practical template for similar Central European municipal heritage entrances.

Heritage staircase accessibility reference:

https://www.sesameaccess.com/knowledge-hub/accessible-heritage-staircase-solutions

Quick Spec Snapshot (preliminary, for coordination)

-

Solution: Hidden platform lift with retracting stairs (Wellington-style)

https://www.sesameaccess.com/lifts/wellington-lift -

Use case: Step-free entrance within listed/heritage context

https://www.sesameaccess.com/knowledge-hub/accessible-heritage-staircase-solutions -

Compliance: CE per Machinery Directive Annex VIII (self-certification + risk assessment)

-

Standards referenced: BS 6440:2011 (informative), EN 81-41 / EN 81-40 not applicable to this product type

-

Pit/Service zone: Under-stair pit with rear access panel from basement; allow for drainage

https://www.sesameaccess.com/knowledge-hub/bespoke-lift-pit-depth-solutions -

Programme: Preliminary drawings now; detailed design next; ~7-month lead-in thereafter

-

Maintenance: Local engineer training by Sesame; rear access panel recommended

https://www.sesameaccess.com/knowledge-hub/export-logistics-bespoke-lifts

All dimensions and interfaces subject to detailed survey and the final Sesame detailed design pack.

Q&A

Q1: Why can’t we use EN 81-41 or EN 81-40?

Because this is an open, concealed platform (not an enclosed shaft lift and not an inclined stairlift). Hence the correct route is Machinery Directive Annex VIII with CE, supported by a detailed risk assessment.

Q2: Do we need a permit at design stage in Hungary for this equipment?

For this category, no design-stage permit; the operational permit is obtained after installation, typically by the main contractor/specialist, referencing the CE documentation.

Q3: What pit details should the architect allow?

A rectangular service space beneath the stair with rear access from the basement and positive drainage. Allow approximately ~1.5 m setback from the bottom riser to the rear of the pit (to be confirmed by survey and Sesame detailed design).

More on pit strategy:

https://www.sesameaccess.com/knowledge-hub/bespoke-lift-pit-depth-solutions

Q4: How do we keep the programme on track?

Lock the detailed design early. Sesame’s bespoke lead-in is ~7 months from detailed design sign-off to delivery; issuing preliminary drawings now enables the CD package while the commercial route for detailed design is finalised.

Q5: Who will service the lift after handover?

Sesame will train a local maintainer. The agreed rear access panel greatly simplifies periodic servicing and inspections.

Servicing/export reference:

https://www.sesameaccess.com/knowledge-hub/export-logistics-bespoke-lifts