Key takeaways

-

Phase 3 transitions the Traversing Lift from the low-profile prototype into a single-scissor, modular architecture.

-

The original 284 mm pit design from Phase 1 and Phase 2 is retained as the shallow-pit benchmark, but Phase 3 introduces a deeper pit to unlock greater stability and smaller platform footprints.

-

Safety remains the primary design driver, with full elimination of crush hazards and improved stiffness at full height.

-

The platform maintains British Standards-compliant usable width while becoming easier and faster to manufacture.

Introduction

The Sesame Traversing Lift programme is being developed through a structured, transparent engineering roadmap.

In Traversing Lift Development – Phase 1, Sesame proved that a hidden, horizontally travelling platform lift could be built in an ultra-shallow pit of approximately 284 mm.

In Traversing Lift Development – Phase 2, that low-profile design was validated for stability, safety and real-world use.

Phase 3 builds on those foundations by shifting the architecture to a single-scissor lift platform. This allows the lift to become smaller in plan, more stable in motion and easier to manufacture, while preserving the safety and discretion achieved in the earlier phases.

How does Phase 3 differ from the Phase 1 and Phase 2 low-profile lift?

The Phase 1 and Phase 2 Traversing Lifts were built around a low-profile lifting mechanism that sat in a pit of approximately 284 mm.

That shallow pit made the lift highly discreet, but it also imposed limits on how high the platform could rise and how far it could traverse while remaining perfectly stable.

Phase 3 deliberately moves away from the low-profile actuator and adopts a single-scissor lift beneath the traversing deck. This introduces more pit depth than the 284 mm prototype, but in return delivers significantly improved stiffness, greater horizontal travel and the ability to reduce the overall platform footprint.

This trade-off is what allows Phase 3 to move from experimental prototype to production-ready system.

How does a deeper pit improve lift stability?

A single-scissor lift has a longer base and a more favourable geometry than a low-profile lift when raised.

By allowing additional pit depth beyond the Phase 1 and Phase 2 benchmark, Phase 3 gains:

-

better resistance to sway at full height

-

higher stiffness under wheelchair loading

-

more consistent platform alignment during horizontal travel

This makes the Traversing Lift feel calmer, more solid and more premium in use, which is critical in public and heritage buildings.

Why use a single-scissor architecture?

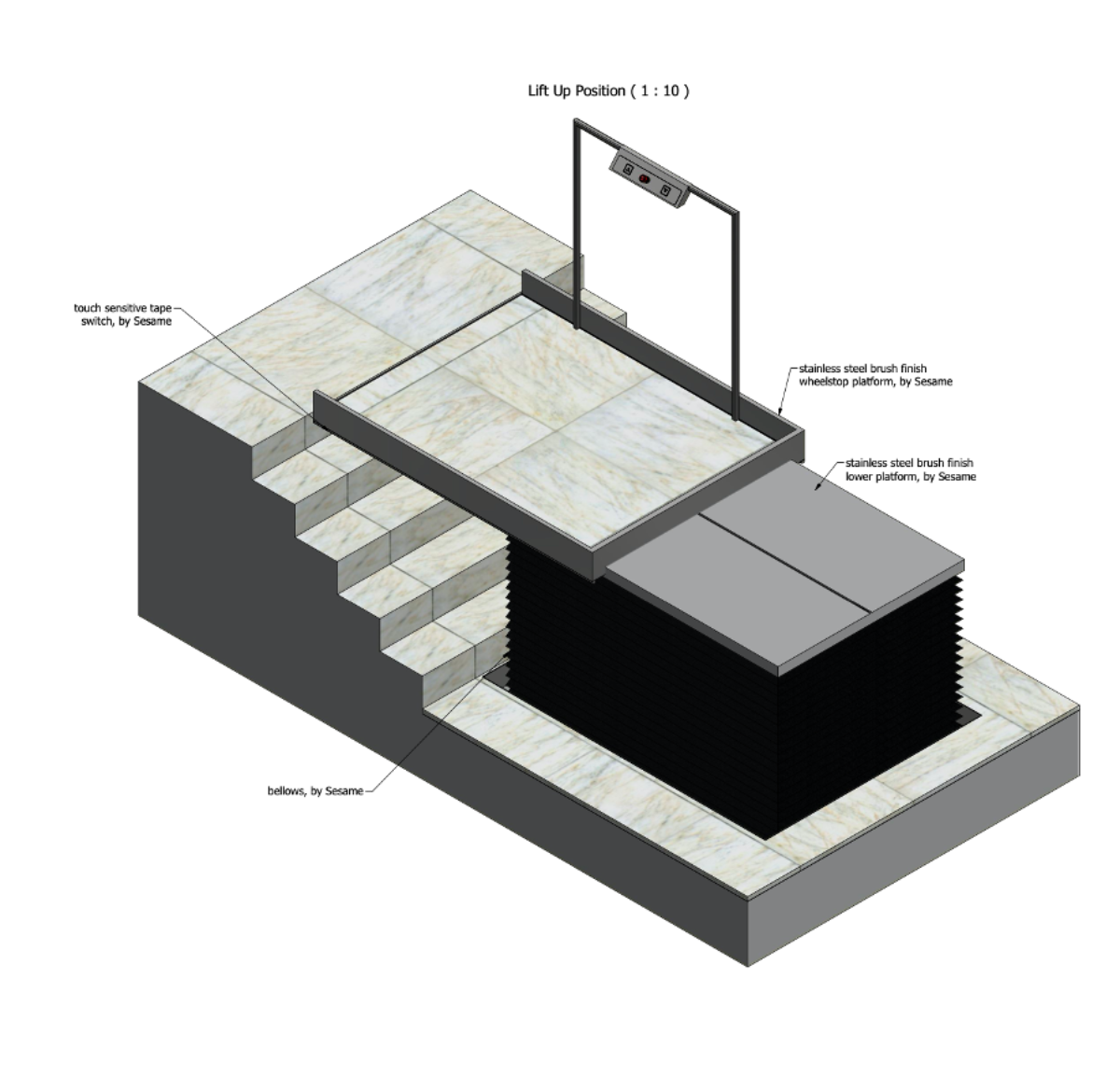

The Phase 3 Traversing Lift is now built as a layered system consisting of:

-

a vertical single-scissor lift

-

a traversing platform module

-

independent wheel-stop and safety assemblies

Feature–benefit structure

-

Single-scissor lift

-

increases stability at full rise

-

allows a narrower overall platform

-

-

Modular traversing deck

-

enables standardised fabrication

-

reduces build time and cost

-

-

Independent safety modules

-

simplify servicing

-

allow future upgrades without redesigning the whole lift

-

This modularity is what allows Sesame to deliver a premium hidden lift with production-grade reliability.

How narrow can the platform be while meeting British Standards?

BS 6440:2011 requires a minimum usable width of 800 mm for wheelchair platforms.

Phase 3 achieves this by providing:

-

approximately 872 mm total platform width

-

800 mm clear usable space once the removable hand-hold post is fitted

This keeps the lift compliant while reducing the opening size required in the floor.

How are crush hazards eliminated?

Phase 3 preserves one of Sesame’s most important competitive advantages.

All areas where movement occurs are protected by:

-

safety edges

-

guided wheel paths

-

full bellows coverage

There are no exposed pinch points where hands, feet or mobility aids could become trapped.

This safety philosophy is shared with discreet lift systems such as the Windsor Lift, Pimlico Lift and Westminster Equality Act Lift.

Why were the bellows redesigned in Phase 3?

Earlier bellows arrangements consumed significant platform width because of brackets, bolts and clearance for movement.

Phase 3 introduces a vertical flat-plate bellows system that bolts directly to the scissor frame and keeps the fabric centred over the moving edge. This reduces side clearances to a fraction of the earlier designs while still providing full protection.

The benefit is more usable platform space and a cleaner, more architectural appearance.

How does the removable hand-hold post work now?

The Phase 3 hand-hold system uses:

-

a threaded floor bush

-

a screw-in aluminium post

-

a flush removable cover

When the post is removed, the floor remains flat and easy to clean. When fitted, the post provides compliant support without bulky sockets or visual clutter.

British Standards compliance

The Phase 3 Traversing Lift continues to meet the key requirements of BS 6440:2011, including:

-

minimum 800 mm usable platform width

-

provision of a hand-hold

-

protected moving edges

-

stable platform behaviour during travel

This allows architects and access consultants to specify the lift with confidence.

Traversing lift vs conventional platform lift

| Question | Conventional platform lift | Sesame Traversing Lift |

|---|---|---|

| Pit depth | often 600–1000 mm | 550 mm |

| Visual impact | visible shaft and doors | fully hidden when parked |

| Crush protection | limited or partial | full safety-edge and bellows system |

| Stability | varies by manufacturer | high-stability scissor architecture |

| Suitability for heritage buildings | often unsuitable | ideal for sensitive interiors |

Frequently asked questions

How much pit depth does the Phase 3 Traversing Lift need?

550 mm, but it remains far shallower than conventional platform lifts.

Why not stay with the 284 mm low-profile design?

The low-profile lift limits stability and platform size. Phase 3 trades some pit depth for much better performance and a smaller footprint.

Is the lift safe while it travels sideways?

Yes. All moving edges are protected by safety edges and bellows, and the wheels are guided to prevent drift.

Is it compliant with UK accessibility standards?

Yes. The platform provides 800 mm usable width and meets BS 6440:2011 requirements.

Call to action

To discuss how the Phase 3 Traversing Lift could work in your building, book a Teams meeting with a Sesame Project Manager:

https://www.sesameaccess.com/book-a-meeting