3D Modelling in Lift Design Assisting Installations

Introduction

Traditional lift installations in complex buildings can suffer from late-stage design clashes, mis-measured components, and unanticipated access restrictions, issues that can delay projects and drive up costs.

3D modelling eliminates these uncertainties by simulating every element of a lift system before it reaches site. Through detailed spatial visualisation, engineers, architects, and builders can see exactly how a bespoke lift will interact with the surrounding structure, long before any metal is cut.

In short, 3D modelling transforms lift installation from reactive problem-solving into proactive precision engineering.

Summary and Key Takeaways

3D modelling improves installation success by predicting physical constraints, enhancing collaboration, and reducing on-site rework.

It allows Sesame Access engineers to test fit, tolerances, and component movement within digital replicas of the client’s site, achieving measurement accuracy within ±2 mm and cutting average installation time by up to 25 percent.

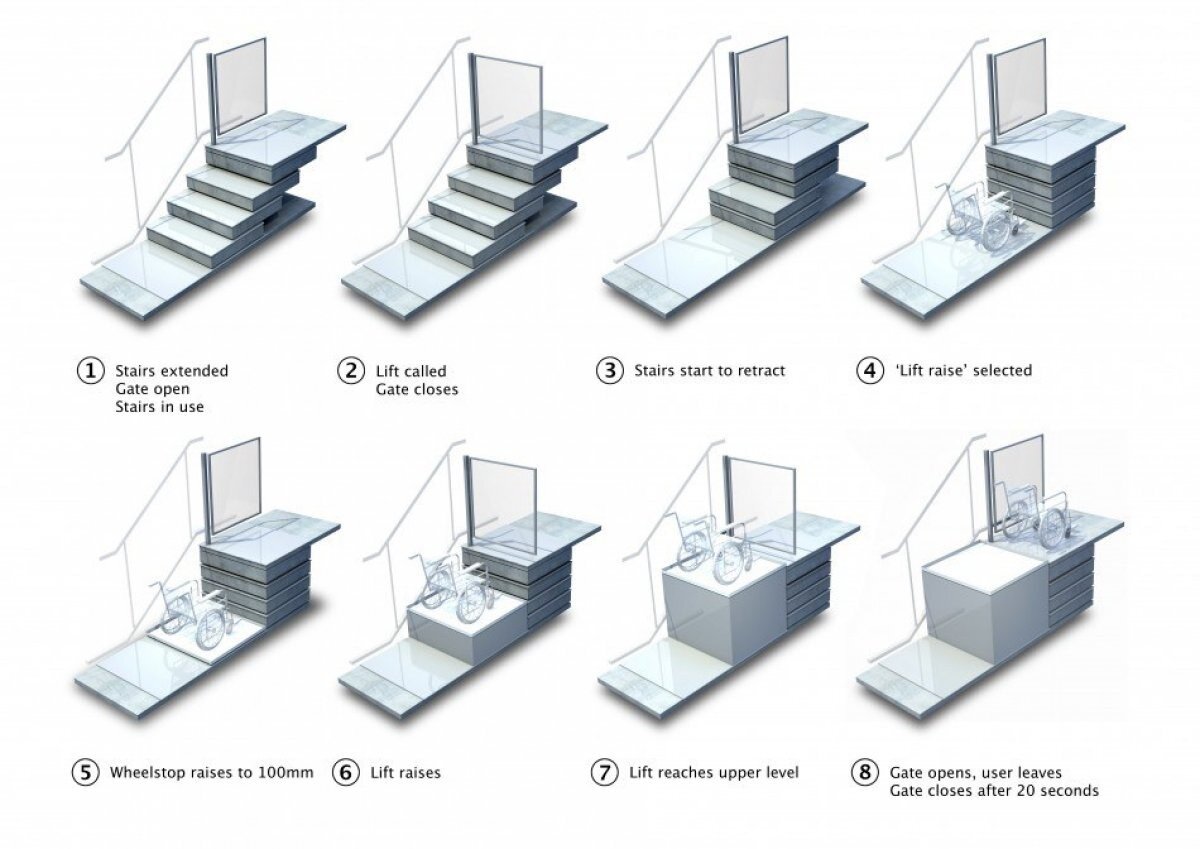

This technology ensures each bespoke lift, such as the Cambridge Part M Lift, Mayfair Stairlift or Richmond Rising Platform Lift, is delivered with exact structural alignment and predictable performance.

How 3D Modelling Improves Lift Design

Modern lift design involves tight architectural tolerances and complex interfaces with flooring, glazing, and stair structures.

3D modelling allows engineers to:

• Verify beam heights, pit depths, and door alignments digitally.

• Identify potential clashes between moving components and existing structures.

• Test multiple configurations to find the most efficient spatial layout.

Each model forms the technical foundation for fabrication drawings, ensuring every bracket and panel fits as intended on site.

Mitigating Installation Risk and Cost Overruns

For architects and contractors, the financial risk of unforeseen issues can be substantial. 3D modelling mitigates these risks by revealing problems in the virtual stage—when they are still inexpensive to fix.

Typical results include:

• Reduction of on-site modification costs by approximately 30 percent.

• Shortened commissioning periods due to pre-validated alignment.

• Clear installation sequencing that eliminates crane and access conflicts.

By rehearsing installation digitally, Sesame engineers create predictable project timelines and safeguard budgets against unexpected variations.

Collaboration and Communication Benefits

3D models serve as a universal visual language between engineering teams, architects, and site managers.

By sharing a single digital model, everyone can coordinate cable containment, power routing, and fixing points without confusion.

This collaborative approach not only improves technical outcomes but also streamlines sign-off processes, reducing communication delays that can hold up site progress.

From Digital Model to Physical Precision

Once validated, dimensional data from the 3D environment flows directly into manufacturing.

Machined parts, laser-cut trims, and structural frames are produced to exact coordinates from the model.

The result is a lift system that aligns seamlessly with the as-built structure, enabling first-time installation accuracy and reducing the need for on-site re-fabrication.

Frequently Asked Questions (FAQ)

What software is used for 3D lift design?

Industry-standard CAD and BIM platforms capable of mechanical simulation and architectural integration.

How accurate are these models?

They achieve measurement precision typically within ±2 mm of as-built conditions.

Can 3D modelling reduce project timelines?

Yes. Digital coordination reduces average installation duration by 20–25 percent.

Why is this important for bespoke lifts?

Because no two installations are identical, 3D modelling guarantees custom fit and compliance from the outset.

How does it support sustainability?

By minimising waste materials and eliminating unnecessary site rework, it supports lower carbon outcomes.