Key Takeaways Architectural variations are common in bespoke lift projects, especially in architect-designed and heritage buildings. A clear five-step variation process protects specification accuracy, finish quality and client approval workflows. Finish changes, plating, powder coating and component additions are fully controlled before manufacturing begins. A structured variation workflow supports high-detail lifts such as the Buckingham listed building lift, Wellington lift and Richmond rising platform lift. Clear communication avoids delays, prevents errors and ensures all updates are fully approved before production.

Introduction Managing architectural variations is an essential part of delivering a bespoke wheelchair platform lift. Whether a project requires new finishes, specialist coatings, updated drawings or additional components, every change must be controlled carefully to protect quality and maintain client expectations. This article explains Sesame Access’s five-step variation management process, designed specifically for complex environments such as heritage buildings, architect-led refurbishments and premium commercial spaces. The process applies equally to hidden stairlift systems, retracting platforms and rising platforms installed in architecturally sensitive settings. For further reading on specialist lift detailing, see hidden lift options with manual barriers and precision lift engineering.

Why Architectural Variations Occur on Bespoke Lifts Variations often arise when a building’s design evolves or when clients refine the appearance of finishes, controls or visible components. The most common reasons include:

Changes to Architectural Finishes and Materials

Requests may include:

- Brass, bronze or stainless-steel electroplating

- Powder-coating in RAL-matched colours

- Updated trim profiles or barrier finishes

- Keypost or control station finish changes

- Additional detail adjustments after sample review

This is especially common on lifts such as the Buckingham listed building lift, where high-precision finish matching is required.

Addition of Components or Functional Features

Architects may request:

- Different handrail specifications

- Modified button stations

- Revised barrier configurations

- Additional safety or control logic elements

These are fully assessed before integration.

Structural or Layout Changes

If building plans shift, the lift specification may need to adjust. Typical examples include:

- Modifying platform dimensions

- Revising pit depths

- Updating barriers to suit new stair geometry

- Incorporating new access routes or hidden mechanisms

This is common for retracting and rotating systems like the Wellington lift.

Five-Step Process: How Sesame Controls Architectural Variations

1. Initial Technical Review

Every variation begins with a technical review to confirm:

- What is changing

- Why the change is required

- Whether further drawings or samples are needed

- Whether the variation affects engineering or installation

This removes ambiguity and ensures all details are fully understood.

2. Communication with Architects and Project Teams

The team confirms:

- What finishes or components are being altered

- Whether the change belongs inside or outside the main contract

- Whether updated drawings are required

- If additional samples or approvals are needed

This stage protects project clarity and avoids duplicated work.

3. Formal Quotation and Client Approval

Once clarified:

- Engineering and finishing costs are calculated

- A formal variation quote is prepared

- The quote is issued to the client or contractor

- No manufacturing or design work begins until written approval or PO is received

This ensures full commercial transparency.

4. Integration into Design, Engineering and Manufacturing

After approval:

- Drawings are updated

- Engineering teams integrate changes

- Finishing partners receive correct specifications

- Any plating or powder-coating is scheduled

- Manufacturing and installation plans are updated

This keeps all departments aligned and avoids incorrect production.

5. Completion, Billing and Sign-Off

Finally:

- Approved variations are logged

- Accounts receive correct values and PO references

- Manufacturing and installation continue with updated details

- The project file is closed with a complete record of any changes

This ensures full traceability for the life of the lift.

How Variation Control Supports Heritage and High-Spec Architecture Variations are particularly important in heritage environments where materials must be sympathetic to the original architecture. Precise control ensures:

- Finish matching aligns with conservation requirements

- Trim and barrier design remains sympathetic

- Hidden mechanisms do not interfere with historic fabric

- Special coatings and metals are selected correctly

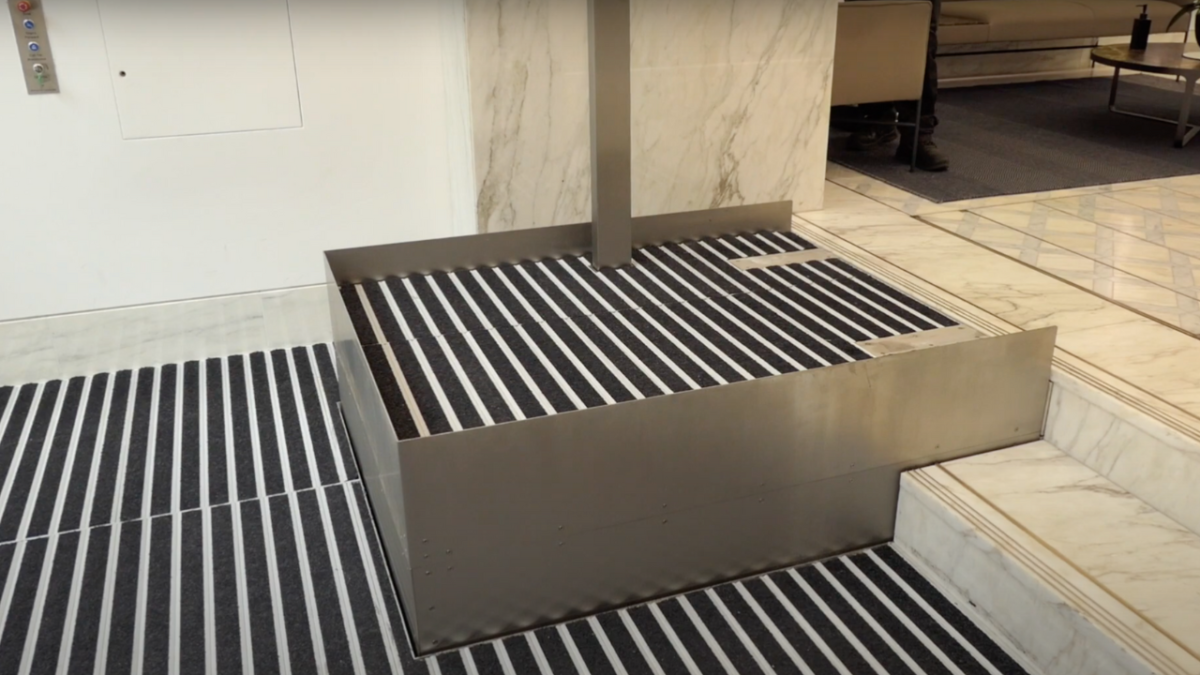

- Detailed lifts like the Richmond rising platform lift integrate seamlessly

This protects both the building and the final presentation.

Related Knowledge Hub Articles Accessible heritage staircase solutions Precision lift engineering

External High-Authority Resource For best-practice guidance on construction variations, contractual approvals and specification control, refer to the detailed guide on Variations in construction contracts.

Frequently Asked Questions (Expanded) What is an architectural variation on a lift project? A variation is any change to the lift’s specification after the initial design, including finish changes, structural updates or added components.

Does a variation slow down the project? A variation can affect timelines if it requires updated drawings, new finish samples or specialist components. Once approved, it is integrated as efficiently as possible.

Can finish samples be reviewed before approving a variation? Yes. Sample approval is common for projects requiring electroplated metals, bespoke trims or heritage-matched finishes.

How are variation costs calculated? Costs depend on engineering effort, materials, finishing processes and any additional manufacturing time required.

Can variations be added after the contract is signed? Yes. Variations can be requested at any stage, provided they are formally approved before work begins.

What if a client changes the lift type entirely? Major variations, such as switching from a rising platform to a retracting stairlift design, require a new quote and full design reassessment.

Do variations require new drawings? If the change affects engineering or installation, drawings are updated before manufacturing.

Can variations impact installation schedules? Yes. Structural or finish-based changes may require adjusted lead times or installation planning.

Who approves a variation? The client or their commercial representative must confirm approval in writing, typically through a purchase order.

Call to Action If you are planning a bespoke lift project and want expert guidance on managing specification changes or architectural variations, you can book a meeting with one of our Project Managers: https://www.sesameaccess.com/book-a-meeting