Key Takeaways

• Explains how bespoke lift partnerships evolve from simple referrals into long-term collaborations.

• Demonstrates how trust, transparency, and shared expertise create sustainable growth for both companies.

• Highlights UK-based design, manufacturing, and project coordination.

• Shows how partners can integrate bespoke platform lifts into wider accessibility and architectural packages.

Introduction

In the world of accessibility design, bespoke lift partnerships solve a crucial problem: how to deliver custom accessibility solutions when off-the-shelf lifts will not fit unique architectural requirements. Following our earlier article Bespoke Accessibility Lift Partnership, this page explores how relationships mature once lift companies commit to deeper collaboration with Sesame Access.

Through transparent communication, shared technical understanding, and joint design processes, these partnerships help expand access to buildings where innovation and precision are essential.

How Do Bespoke Lift Partnerships Evolve Over Time?

Partnerships typically begin with shared enquiries or project referrals. Over time, as both teams gain confidence in each other’s strengths, they move toward coordinated project delivery. Lift companies can offer their clients a complete package, while Sesame provides bespoke engineering and accessibility expertise.

This relationship allows both parties to work with architects, main contractors, and design consultants to deliver elegant accessibility solutions that fit within complex environments. For example, a recent collaboration involved a fully integrated stage lift designed to disappear into its surroundings, a testament to what’s possible when bespoke design meets trust-based cooperation.

For related insights, see Bespoke vs Standard Platform Lifts – Understanding the Difference and Sesame-access-global-installs.

What Makes Sesame’s Collaborative Process Different?

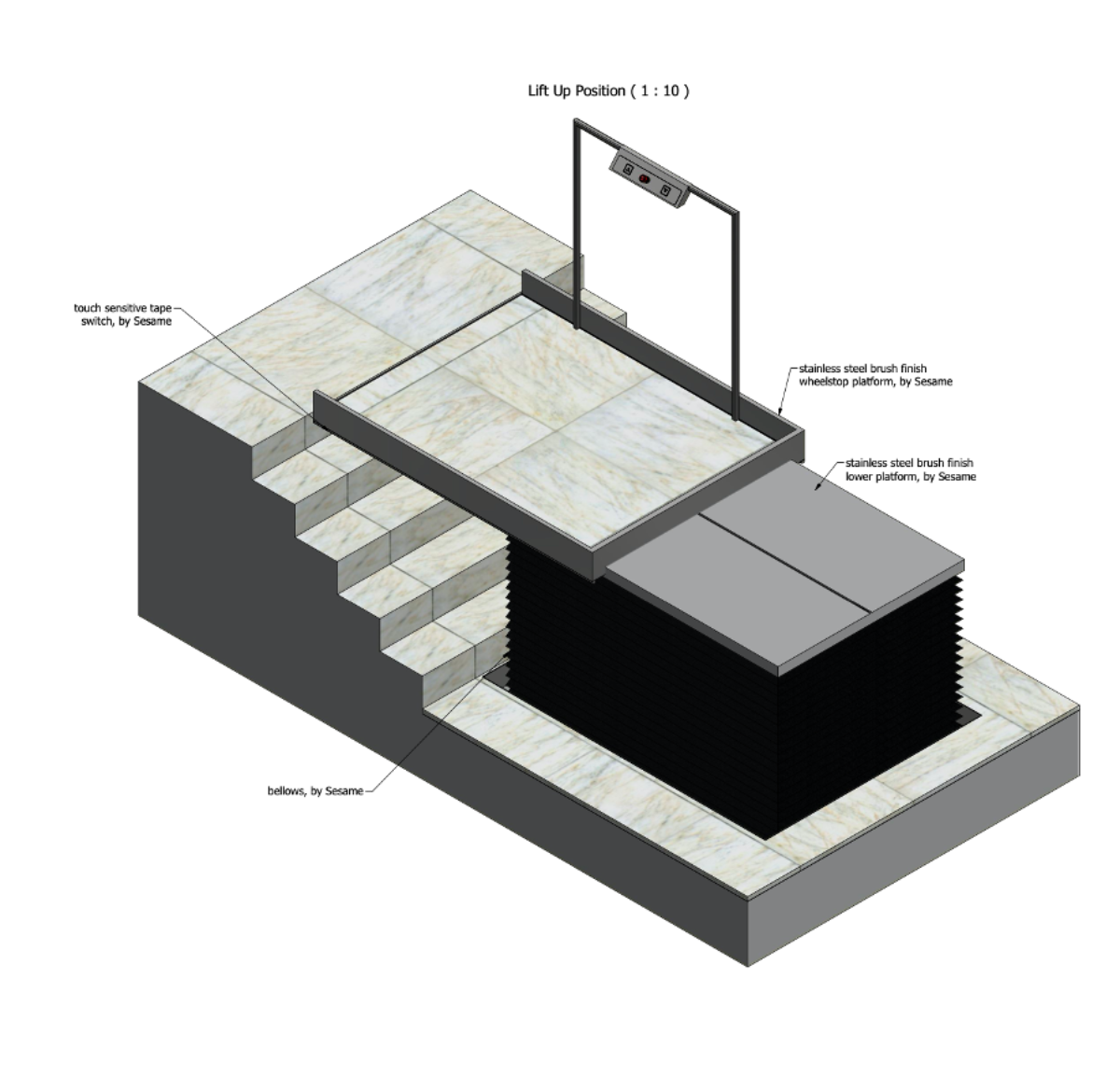

Sesame Access supports every partner with a transparent workflow and detailed technical guidance. Each enquiry is logged through an internal project system to ensure accountability. Bespoke drawings, structural load data, and pit details are shared during early design phases without charging upfront fees.

This clarity helps architects and engineers make informed decisions while ensuring partners can present a well-supported technical proposal to their own clients. Such openness allows lift companies to focus on building client relationships while Sesame handles complex design work.

Why Do Partners Value UK Manufacturing and Bespoke Platform Lifts?

UK-based manufacturing gives partners direct access to Sesame’s engineering team, providing consistent quality control and rapid feedback on design iterations. Every lift is custom-built to the site’s geometry, ensuring compliance with modern accessibility standards.

Recent solutions include stage-integrated lifts, compact platform lifts for limited pit depths, and custom Equality Act-compliant systems for heritage buildings. These designs showcase the precision and flexibility possible with bespoke platform lifts created in the UK.

Partners who visit our Surrey workshop often comment on the craftsmanship and the stability of our scissor-lift mechanisms compared to imported alternatives.

What Benefits Do Lift Companies Gain from Collaboration?

Deeper partnerships bring mutual benefits:

• Expanded service offerings without added in-house engineering costs.

• Access to a portfolio of proven, UK-built accessibility products.

• Transparent project tracking and client coordination.

• Shared marketing opportunities to reach higher-end architectural markets.

This model allows lift companies to operate confidently in premium design sectors while ensuring each client experiences a unified, seamless service.

Related Services and Next Steps

Partners often start their journey with products designed for architectural integration and inclusive design goals, such as:

• Retracting stairlift systems for heritage entrances.

• Compact platform lifts for small urban sites.

• Custom lifts addressing complex Equality Act or DDA requirements.

To explore which product best complements your client portfolio, view our range of bespoke lifts including the Buckingham Listed Building Lift and Traversing Lift.

Frequently Asked Questions (FAQ)

What type of companies can collaborate with Sesame Access?

Any established lift or accessibility business interested in bespoke engineering projects is welcome to collaborate.

Does Sesame handle design and technical support?

Yes. We provide detailed drawings, pit dimensions, and load calculations so architects and engineers can plan installations accurately.

What is the usual project duration for a bespoke lift?

Typical projects range from four to six months from initial design approval to installation, depending on site conditions and required customisation.

What warranty do Sesame lifts include?

All bespoke lifts come with a standard 12-month warranty and optional extended service contracts that include full callout cover.

Can partners visit the Sesame workshop?

Yes. We welcome visits to our Surrey facility to meet the engineering team and review active builds.

How are client enquiries managed?

All enquiries are logged and tracked through our project system to ensure transparency. Partners receive updates at every key stage.

Call to Action

If your company is ready to develop a long-term, transparent partnership with Sesame Access, our team would be delighted to explore how bespoke lift solutions can enhance your client projects.

Book a Teams Meeting with our Project Managers to discuss collaboration opportunities.