Key Takeaways

-

Site-specific lift drawings can be issued fast enough to support live planning submissions.

-

Editable DWG files allow architects to integrate lift design directly into their planning sets.

-

Planning officers respond better to proposals backed by real, buildable engineering detail.

-

External, heritage-sensitive sites benefit most from early technical input.

-

Sesame Access has delivered over 400 bespoke lifts to date, with no planning refusals recorded across applicable submissions.

Introduction: Why Planning Success Often Depends on Drawings, Not Concepts

In sensitive planning contexts, particularly external or heritage-adjacent sites, the difference between approval and delay often comes down to the quality of the technical information submitted.

Generic lift references rarely provide enough confidence. Planning officers want to see how an access solution actually fits the site, how it will be built, and whether it has been properly resolved from a safety and compliance perspective.

This article explains how Sesame Access supported a tight planning timeline by delivering site-specific, editable lift drawings quickly enough to be used directly within a planning application, without redesign or rework.

The Problem: A Tight Planning Window With No Margin for Redesign

The design team was working towards a fixed submission deadline and required drawings that demonstrated a realistic, compliant lift solution rather than an indicative concept.

Key challenges included:

-

A constrained external footprint

-

A rise of over 2.4 metres requiring careful platform sizing

-

Drainage considerations below ground

-

Adjacent walls and finishes requiring precise safety tolerances

-

A need to reassure planning officers that the proposal was buildable

As noted during the technical review:

“Just download that and stretch everything in plan and section the pit, the platform, everything scales with it.”

That level of flexibility was essential for keeping the planning programme on track.

The Solution: Rapid Issue of Site-Specific DWG Drawings

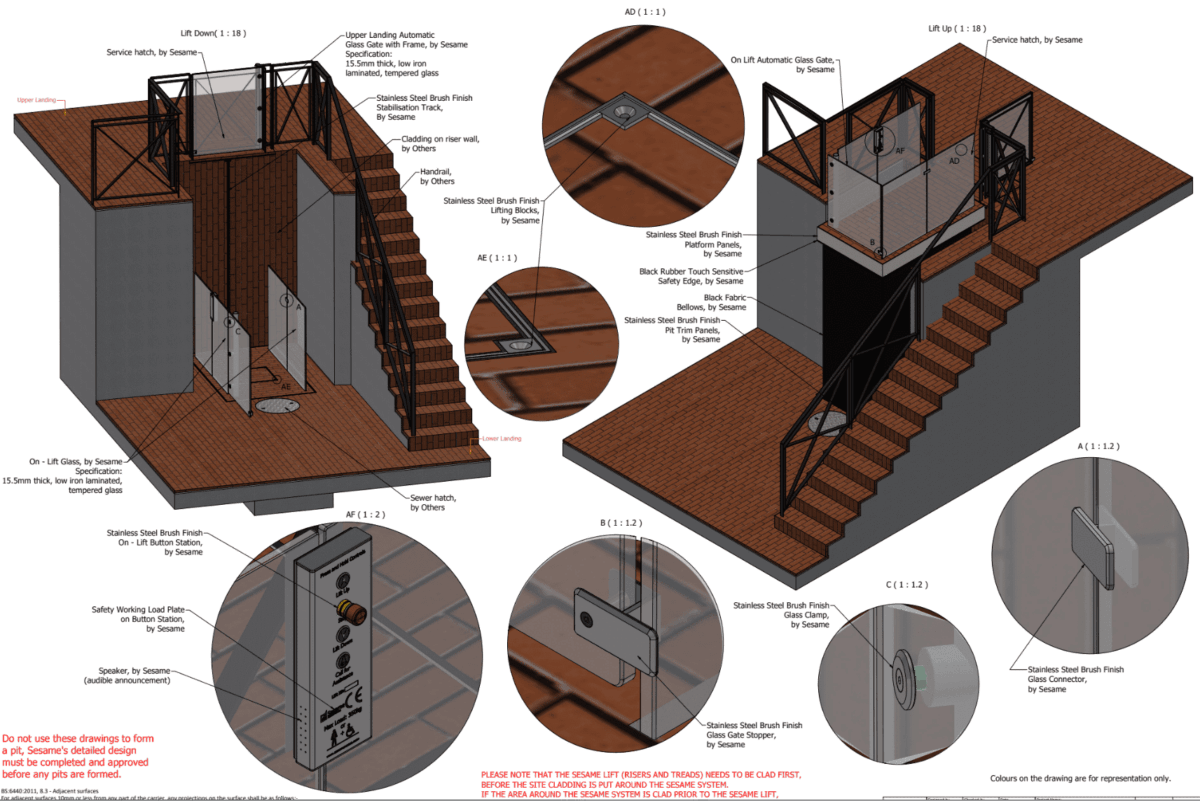

Instead of providing generic PDFs, Sesame Access issued editable DWG drawings tailored to the exact site conditions.

These drawings showed:

-

Platform length scaled to suit the confirmed rise

-

Accurate pit depth and below-ground build-up

-

Stabilisation tracks and guidance systems

-

Safety zones aligned with British Standards

-

External drainage strategies appropriate to a flat site

Because the drawings were native CAD files, the architect was able to integrate them directly into the planning set without redrawing or interpretation.

As discussed in the session:

“That’s your drawing, that’s your system stabilisation tracks, that’s everything there.”

Authority Through Experience, Not Assumption

Sesame Access engineering guidance is based on real installations, not theoretical layouts.

Across more than 400 installed bespoke lifts, including planning-sensitive and heritage-adjacent environments, the same principles are applied consistently. Where applicable, no planning refusals have been recorded when proposals are supported by resolved technical drawings and early coordination.

This experience underpins the advice given to architects and planners at pre-application and submission stage.

How This Aligns With Listed and Sensitive Planning Contexts

Early technical drawings are particularly valuable when dealing with listed buildings or visually sensitive front or rear elevations.

For a deeper exploration of how early access strategies support planning outcomes, see

Front door lift planning strategies for listed buildings

Where concealed or visually minimal solutions are required, drawings must demonstrate not only compliance, but restraint.

Guidance on how concealed lifts are assessed against British Standards is covered in

Hidden lift design standards and BS6440 Annex VIII

BS6440 Safety Tolerances: Why “Plumb and Flush” Actually Matters

One of the most important planning-stage clarifications relates to adjacent wall finishes and safety gaps.

British Standard BS6440:2011 defines acceptable gap conditions as either less than 10mm or greater than 100mm to avoid finger or limb entrapment.

As explained during the review:

“Less than 10mm or more than 100mm, that’s the standard. Everything else creates risk.”

This directly affects how brickwork, mortar joints, and finishes must be detailed. Standard indented mortar joints are often unsuitable, and flush finishes need to be clearly shown on drawings to avoid site issues later.

When to Specify External Drainage and Sump Pumps

Drainage strategy is another area where generic references frequently fail at planning stage.

Where gravity drainage is available, it is always preferred. However, on flat sites, an external sump pump with a serviceable hatch is often the safest and most maintainable option.

As discussed:

“If you’ve got gravity drainage, that’s always best, otherwise we plan a sump pump that can actually be accessed and maintained.”

Locating the sump externally avoids long-term maintenance risks and reassures both planners and building owners that the system can be serviced without removing the lift.

Common Misconceptions Corrected at Planning Stage

Manufacturer drawings cannot be used in planning submissions

In reality, site-specific DWG drawings are regularly incorporated directly into planning sets when they are accurate and editable.

Sump pumps must sit inside the lift pit

External sump pits with service hatches are often preferable for maintenance and long-term reliability.

Bellows are visually intrusive

High-rise bellows are largely concealed when the lift is at rest and are only visible during travel, making them suitable for discreet external installations.

All adjacent walls must be plumb and flush

Only walls within defined safety zones require strict tolerances. Walls set back beyond 100mm can be finished more flexibly.

When This Approach Is Right, and When It Isn’t

This approach is particularly effective when:

-

The site is external or visually sensitive

-

Planning timelines are tight

-

A bespoke or concealed platform lift is proposed

-

The architect needs drawings that integrate directly into CAD

-

Compliance questions are likely to be raised early

A different approach may be more appropriate when:

-

The site is internal with standard clearances

-

Planning is not required

-

A standard off-the-shelf platform lift is acceptable

-

Visual impact is not a planning concern

Early technical conversations help determine which route is appropriate before time and cost are committed.

Constraint-Led Specification Matrix

| Site Constraint | Engineering Decision |

|---|---|

| Rise over 2,400mm | Platform length scaled to approximately 1,800mm |

| External location | Drainage strategy defined at drawing stage |

| Flat site | External sump pump with service hatch specified |

| Adjacent wall within 100mm | Plumb and flush finish required |

| Adjacent wall over 300mm | Reduced safety constraints apply |

| Planning sensitivity | Concealed platform lift solution referenced |

Relevant Lift Solutions Referenced

The planning drawings aligned most closely with the following solutions:

-

Windsor Lift – concealed platform lift for constrained sites

-

British Library Platform Lift – high-spec concealed access lift

These references help planning officers understand precedent without overwhelming the submission.

Frequently Asked Questions

Can site-specific lift drawings be issued before planning approval?

Yes. Drawings are often produced specifically to support planning submissions and refined later if required.

Are these drawings suitable for listed or heritage-adjacent sites?

They are designed to address visual sensitivity, compliance, and buildability in planning-led contexts.

Do planning officers accept manufacturer-issued drawings?

When drawings are site-specific, editable, and integrated into the architect’s set, they are commonly accepted.

How quickly can drawings be issued?

Once constraints are confirmed, initial technical packs can often be issued within days rather than weeks.

Next Steps

If you are working towards a planning deadline and need credible, site-specific lift drawings that can go straight into your submission, speak directly with a Sesame Access Project Manager.

Book a Teams meeting here:

https://www.sesameaccess.com/book-a-meeting

Early technical clarity almost always saves time later.