Key Takeaways

-

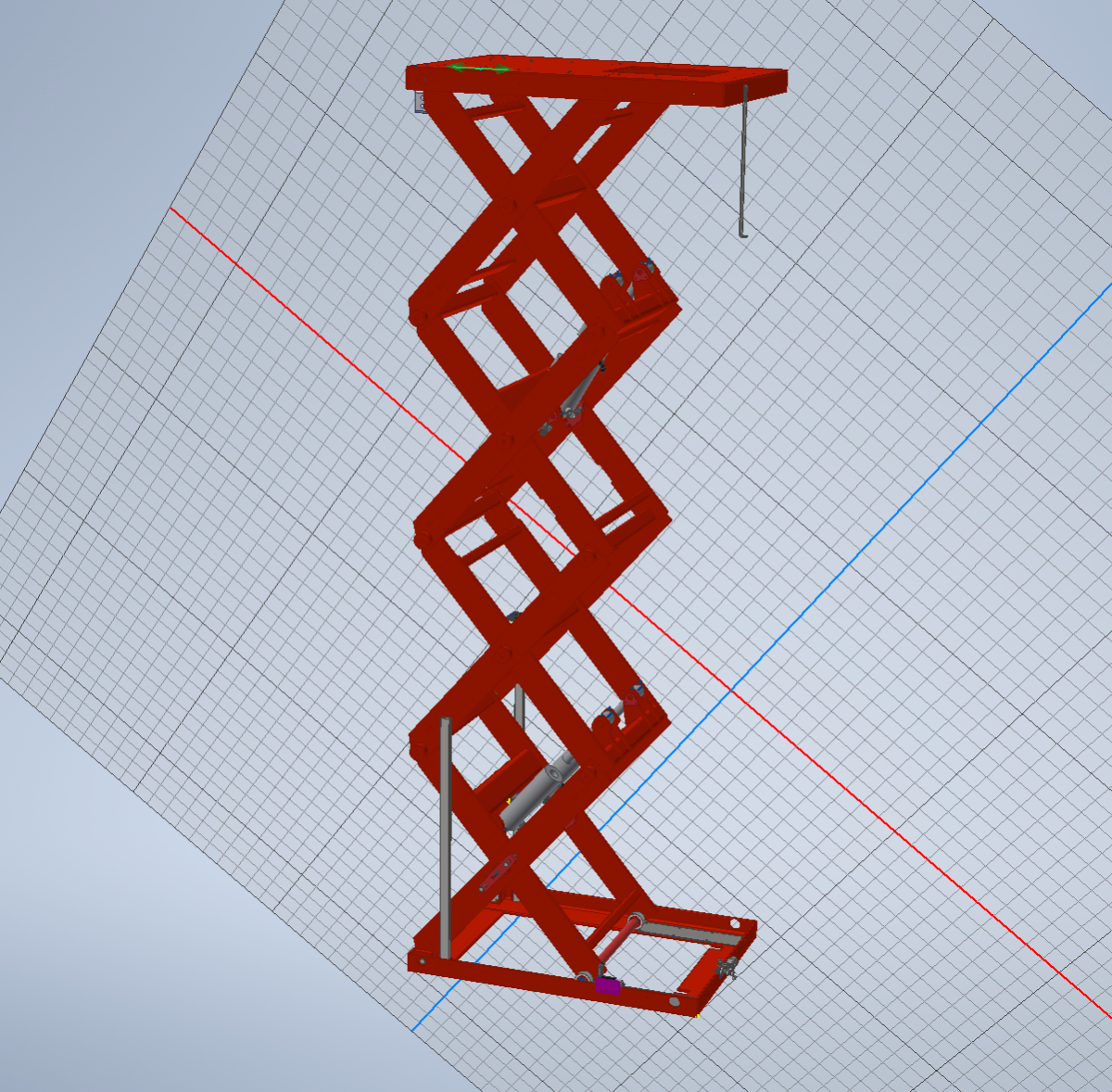

A bespoke scissor lift was engineered to deliver a full 3-metre rise within a corridor width of just 1370–1455 mm.

-

The lift uses a stretched 1250 mm scissor mechanism, adapted from previous quadruple-scissor engineering used on complex international projects.

-

Pit depth remains approximately 700 mm, making the solution viable for terrace houses with minimal excavation capacity.

-

Earlier stages of this enquiry explored standard options such as the Windsor Lift (https://www.sesameaccess.com/lifts/windsor-lift), the Edinburgh Access Lift (https://www.sesameaccess.com/lifts/edinburgh-access-lift), and moat-style approaches.

-

Safety edges, bellows, guidance channels and gate orientations were engineered specifically to eliminate crush hazards under BS 6440 and UK Part M constraints.

Introduction

Terrace houses often present some of the most restrictive conditions for accessibility engineering, especially where architects need to achieve a three-metre rise within a narrow internal footprint. In this stage of the enquiry, the team explored a bespoke scissor lift capable of providing full vertical travel in a corridor only 1370–1455 mm wide. Because no standard hidden lift could physically fit or meet the rise, the engineering effort focused on creating a new bespoke scissor lift mechanism tailored precisely to the site.

This followed three earlier feasibility phases: the London terrace-house concept (https://www.sesameaccess.com/knowledge-hub/london-terrace-house-platform-lift-solution), the Windsor vs Edinburgh comparison (https://www.sesameaccess.com/knowledge-hub/terrace-house-windsor-vs-edinburgh-platform-lifts), and the moat-platform solution study (https://www.sesameaccess.com/knowledge-hub/terrace-house-bespoke-moat-platform-lift). Together these revealed that no existing product could achieve the required geometry or compliance.

Why Standard Lifts Could Not Work

Several Sesame products were considered during feasibility, including the Windsor Lift (https://www.sesameaccess.com/lifts/windsor-lift), the Edinburgh Access Lift (https://www.sesameaccess.com/lifts/edinburgh-access-lift), and the Westminster Equality Act Lift (https://www.sesameaccess.com/lifts/westminster-equality-act-lift). Each was ruled out for one of the following reasons:

-

Insufficient travel height for a 3-metre rise

-

Platform lengths too large to fit inside the corridor

-

Requirements for wall flushness or enclosure that the building could not accommodate

-

Pit depth or guidance-track constraints around the structural archway

To help architects and consultants quickly understand the restrictions, the following table summarises the technical limitations:

Standard Lift Limitations vs Bespoke Solution

| Requirement | Standard Hidden Lifts | Bespoke Scissor Lift |

|---|---|---|

| Required travel | Up to 1 metre (typical) | Full 3 metres |

| Corridor width | Often requires >1500 mm | Works within 1370–1455 mm |

| Pit depth | 600–1600 mm | Approx. 700 mm |

| Platform length | Fixed per model | Custom 1250 mm stretched scissor mechanism |

| Safety compliance | Within BS 6440 and Part M | Customised edges, bellows, sensors and gate geometry, Machinery Directive Annex VIII |

| Archway and wall interfaces | Not optimised | Fully site-specific |

Engineering the Bespoke Quadruple-Scissor Mechanism

The process had the Sesame engineering team evaluated a quadruple-scissor configuration originally used on international projects requiring significant travel in restricted footprints. The core principle is that short-arm X and Y axes can generate high vertical movement with minimal scissor length.

By stretching the scissor from 1000 mm to 1250 mm, the team confirmed through mechanical testing that a full 3-metre stroke could be achieved without overstressing the structure. This approach retained proven components while adapting geometry to the terrace-house environment.

Integrating Safety: Edges, Bellows, Gates and Wall Geometry

Given the corridor pinch points, each safety element had to be engineered to avoid narrowing the platform while still complying with BS 6440:

-

Safety edges were fitted directly to the lift table rather than to surrounding walls.

-

Bellows were positioned only where crush hazards existed, reducing unnecessary encroachment.

-

Guidance tracks were considered both within the wall build-up and on the lift side, depending on final dimensions.

-

A roller-blind style under-bridge protection was explored to remove risk zones beneath the rising platform.

-

Gate clearance was calculated to retain an entry width of approximately 850–950 mm, meeting Part M expectations.

The Equality Act requirement for safe, independent use was considered throughout, ensuring that users remain protected even in high-risk compression areas such as the underside of the decorative arch.

How This Fits Into the Four-Part Terrace House Series

This article represents the pivot point where the project moved beyond evaluating existing lifts into the creation of a brand-new bespoke system. Earlier articles established:

-

The building constraints and rise requirement

-

The comparison between standard retracting stair-lift configurations

-

The intermediary moat-lift approach for complex lower-ground connections

-

The final bespoke scissor lift designed specifically to achieve a 3-metre rise in minimal space

This progression reflects the typical design arc for restricted heritage or terrace sites where off-the-shelf technology cannot deliver compliance.

Other Knowledge Hub Articles

-

Hidden Lift Design Standards: BS 6440 and Annex VIII

https://www.sesameaccess.com/knowledge-hub/hidden-lift-design-standards-bs6440-annex-viii -

Export Logistics for Bespoke Lifts

https://www.sesameaccess.com/knowledge-hub/export-logistics-bespoke-lifts

Frequently Asked Questions

Can a lift really achieve a 3-metre rise in a narrow terrace house?

Yes. A bespoke scissor arrangement can achieve this within a 1370–1455 mm corridor width.

Why was a bespoke scissor lift chosen?

Standard products cannot deliver the required rise without exceeding space limits or compromising safety. A custom mechanism resolves these geometric constraints.

Is the pit depth unusually deep?

No. At roughly 700 mm, the pit depth aligns well with typical terrace-house tolerances.

Does the solution comply with BS 6440 and Part M?

Yes. Safety edges, bellows, gate positioning and under-bridge protections are designed specifically to meet the relevant clauses. The rise must sit below 3000mm as lifts with a rise larger than this need a shaft.

Will architects receive site-specific drawings?

Yes. Full detailed drawings are produced once the concept is confirmed.

Call to Action

If you are working on a challenging terrace-house or narrow-access project, our engineering team can help you explore viable and compliant solutions.

Book a meeting with one of our Project Managers:

https://www.sesameaccess.com/book-a-meeting