Key Takeaways

-

Accessibility in heritage buildings often fails when standard platform lift geometry is applied without adaptation.

-

BS 8300 turning circle requirements can be met through movement sequencing rather than static footprint alone.

-

Sesame Access delivers site-specific engineering solutions that balance Equality Act compliance, planning sensitivity, and real user behaviour.

-

Managed access strategies with staff oversight can unlock safer solutions in hospitality and listed contexts.

Problem → Solution Overview

| Traditional Approach | Sesame Access Approach |

|---|---|

| Rectangular platform sized to static standards | Non-rectangular bespoke platforms engineered around real movement paths |

| Full 1500 mm turning circle forced inside lift | Turning achieved through staged movement and 90-degree return zones |

| Swing gates creating arc conflicts | Rising safety barriers integrated with heritage ironwork |

| Generic compliance assumptions | Equality Act compliance in heritage contexts through risk-based design |

| Off-the-shelf systems | Fully site-specific engineering responding to glazing edges, ledges, and columns |

| Unmanaged public operation | Managed access with trained staff oversight in hospitality settings |

This distinction is critical in constrained heritage environments where conventional solutions introduce new hazards rather than removing them.

Introduction

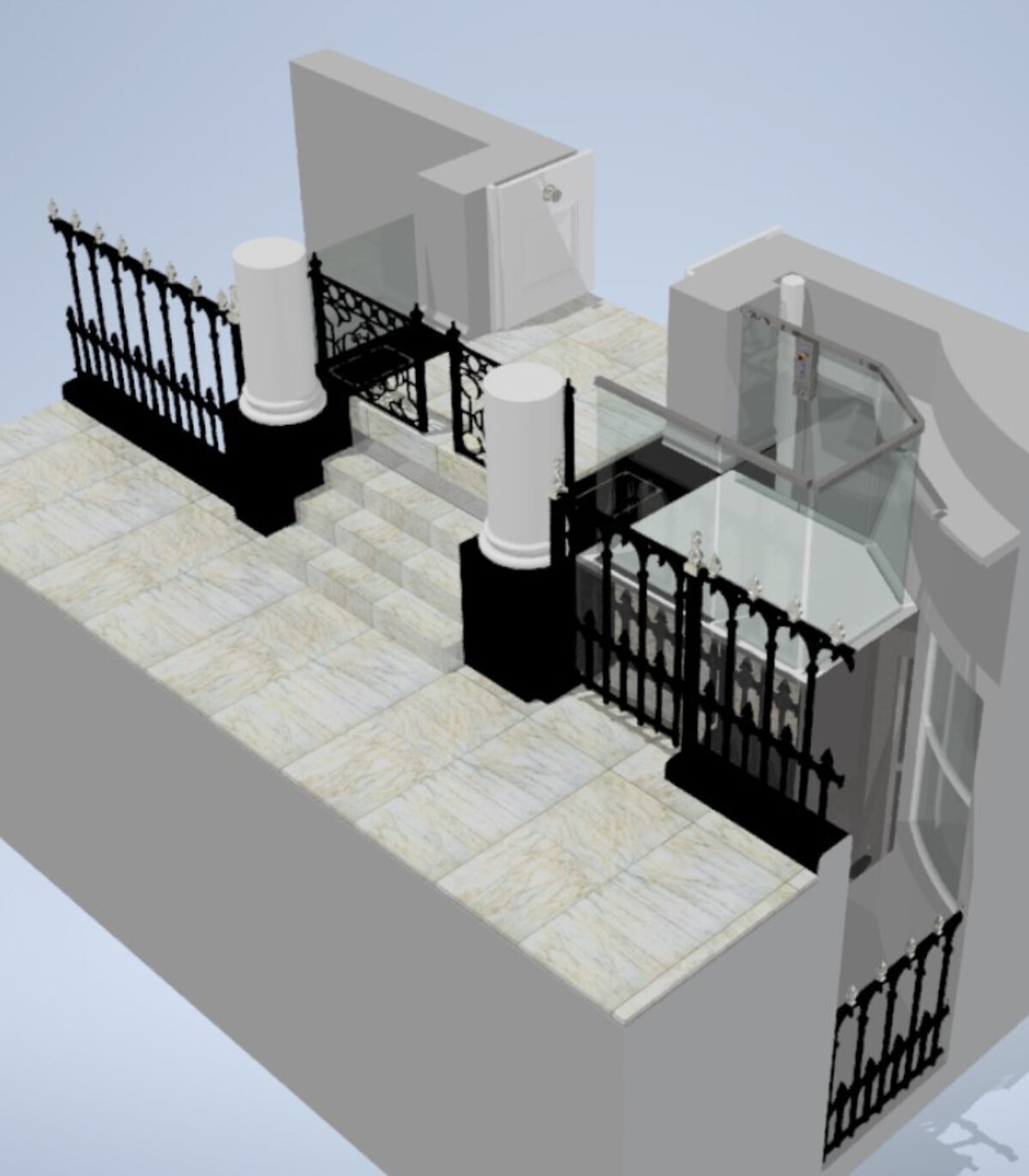

Designing an accessible entrance within a heritage building rarely begins with a blank canvas. Architects and access consultants are often presented with fixed staircases, existing ironwork, glazing, and strict planning constraints that limit structural intervention.

This article documents how Sesame Access evolved a complex entrance solution through iterative design, 3D modelling, and technical validation. It follows on from earlier analysis in heritage hotel accessible entrance solutions and demonstrates how people-first engineering can achieve Equality Act compliance without compromising architectural integrity.

The Core Challenge: BS 8300 Turning Circles vs Physical Reality

Standards such as BS 8300 reference a 1500 mm turning circle to accommodate wheelchair manoeuvring 360 degrees. In constrained entrances, especially those adjacent to staircases and glazing, providing this turning circle entirely within a platform lift footprint can be physically impossible.

In this case, forcing a compliant rectangle would have pushed users toward glazing edges and window ledges, introducing collision and fall risk. The issue was not regulatory intent, but literal interpretation.

The design question therefore shifted from “how do we fit the diagram” to “where does the user actually turn, pause, and realign during use”.

Movement-Based Engineering Rather Than Static Geometry

Through detailed modelling, the team analysed approach angles, boarding positions, and exit behaviour. This allowed the turning movement to occur across staged zones rather than in one static footprint.

The resulting solution combined:

-

A non-rectangular bespoke platform designed to avoid glazing edges and ledges

-

A rising safety barrier replacing swing gates where arcs would clash

-

Independent vertically moving steps that temporarily form a level upper landing

This approach mirrors principles used in bespoke Windsor platform configurations for constrained spaces

https://www.sesameaccess.com/lifts/windsor-lift

and in projects where retracting step technology is integrated with lift travel, such as the Wellington system adapted for heritage entrances

https://www.sesameaccess.com/lifts/wellington-lift

Safety Engineering in Constrained Environments

As the geometry evolved, detailed safety considerations became critical. These included:

-

Platform lift weight capacity for glass barriers and rising mechanisms

-

Emergency lowering procedures that remain functional with glass and stainless-steel barriers

-

Solid safety edges replacing floor tape switches in high-traffic boarding zones

-

Avoidance of crush hazards near existing iron railings and glazing returns

Rather than introducing excessive guarding, the solution relied on precise placement and sequencing, supported by physical safeguards where user contact is most likely.

Managed Access and Staff Oversight as a Safety Strategy

In hospitality and prestigious heritage buildings, while it is always preferable, not all access solutions need to be fully unmanaged. In this case, the final design assumed managed access with trained staff oversight.

This allowed:

-

Controlled operation during lift movement

-

Visual confirmation of safe boarding and exit

-

Reduced need for intrusive guarding or over-scaled enclosures

Managed operation is an established accessibility strategy where public dignity, safety, and architectural preservation must coexist.

Product Integration Summary

| Design Requirement | Engineering Response | Related Sesame Solution |

|---|---|---|

| Constrained footprint beside stairs | Bespoke platform geometry | https://www.sesameaccess.com/lifts/windsor-lift |

| Upper landing height change | Independent moving steps | https://www.sesameaccess.com/lifts/wellington-lift |

| Fall risk near heritage ironwork | Rising barrier with solid safety edge | https://www.sesameaccess.com/lifts/westminster-equality-act-lift |

Each system is adapted rather than installed as a fixed product, reinforcing Sesame Access’s site-specific engineering philosophy.

Why This Matters for Architects and Access Consultants

This project demonstrates that Equality Act compliance in heritage contexts does not require compromise on safety or dignity. By designing around real user movement, rather than idealised diagrams, access solutions can be safer, more elegant, and more acceptable to planners.

The key is recognising when standard layouts cease to serve real people, and having the engineering capability to respond.

Frequently Asked Questions

Is a full 1500 mm turning circle always required inside a platform lift?

No. BS 8300 intent can be met through staged turning and 90-degree return zones when supported by appropriate safety measures. Lifts with adjacent entrance/exit routes require a minimum usable surface area of 1100mm x 900mm on the platform.

Are non-rectangular platforms compliant?

Yes, when the usable space and movement outcomes meet accessibility requirements and are risk-assessed correctly.

How does managed access affect compliance?

Managed access with staff oversight is acceptable in hospitality and controlled environments when documented and justified.

Do glass rising barriers affect emergency lowering procedures?

They can, which is why barrier weight, mechanism selection, and manual lowering protocols must be engineered together.

Is this approach suitable for listed buildings?

Often yes, because it reduces permanent alteration and visual impact compared to ramps or enclosed lift shafts.

Next Step

If you are facing a constrained or sensitive access challenge, speak directly with an engineer.

Book a Teams meeting with a Sesame Access Project Manager

https://www.sesameaccess.com/book-a-meeting