Key Takeaways

• Lifting plan coordination ensures bespoke platform lifts integrate precisely with site steelwork and architectural finishes.

• Structural verification, clash detection, and 3D modelling identify issues before installation.

• Clear dimensional control between the SESR (Sesame top step Riser) and SESC (Sesame Centreline) reference lines prevents costly on-site corrections.

• Coordination between design, fabrication, and installation teams guarantees a compliant, durable accessibility solution.

Introduction

Lifting plan coordination is a cornerstone of bespoke lift engineering. It transforms complex architectural environments into clear, measurable frameworks ready for installation.

At Sesame Access, engineers use advanced 3D modelling, clash detection, and as-built verification to ensure that every component, lift frame, pit trim, and riser wall, fits exactly as designed.

This meticulous approach minimises installation delays and maintains full compliance with accessibility and safety standards.

How Do You Coordinate a Lifting Plan?

The coordination process begins long before any lifting takes place. It combines digital modelling with on-site verification to align every trade involved in the build.

When a project includes structural steelwork or fireproofed columns, engineers first confirm real-world dimensions against architectural drawings. These checks are then merged into a 3D model showing how the lift structure interacts with stairs, walls, and doors.

By doing this, Sesame Access eliminates the risk of on-site clashes and ensures clearances such as 8 mm to 20 mm remain within approved tolerances for European installations.

What Measurements Are Needed for Platform Lift Installation?

Accurate dimensional data forms the backbone of each lifting plan. Key measurements include:

• SESC (centreline) and SESR (riser line) positions

• Beam heights and offsets at upper and lower landings

• Distances from riser wall to doorways and stair treads

• Service-hatch alignment for maintenance access

For example, when installing a lift in a heritage stairwell with tight I-beam clearances, engineers verify that the fireproof cladding thickness does not push the column beyond the 8 mm lift gap limit. This type of technical precision allows bespoke lifts to operate safely within constrained architectural spaces.

Step-by-Step Coordination Process

-

3D modelling and clash detection: Engineers generate a site-accurate model linking architectural, structural, and mechanical elements.

-

Structural verification: On-site steelwork and cladding are checked against digital drawings to identify any deviation in beam levels or pit dimensions.

-

Tolerance mapping: Real measurements are compared with design tolerances to determine if adjustments are required before manufacture.

-

As-built documentation: Final verified drawings are produced and shared with architects, ensuring everyone works from a single, coordinated plan.

-

Installation alignment: During installation, engineers confirm that all fixing points and service access locations match the verified drawings.

Throughout this process, clear communication with builders and design consultants ensures no step is missed between model and reality.

How 3D Modelling Enhances Lift Installation Accuracy

3D visualisation gives architects and site teams a transparent view of how every element fits together. It helps coordinate containment routes, lighting, and control panels while preserving the visual quality of the finished environment.

By simulating movement and spatial relationships before any fabrication begins, Sesame engineers can test multiple lift configurations in digital space, saving both time and material once on site.

Integrating Lifting Plans Across Sesame Products

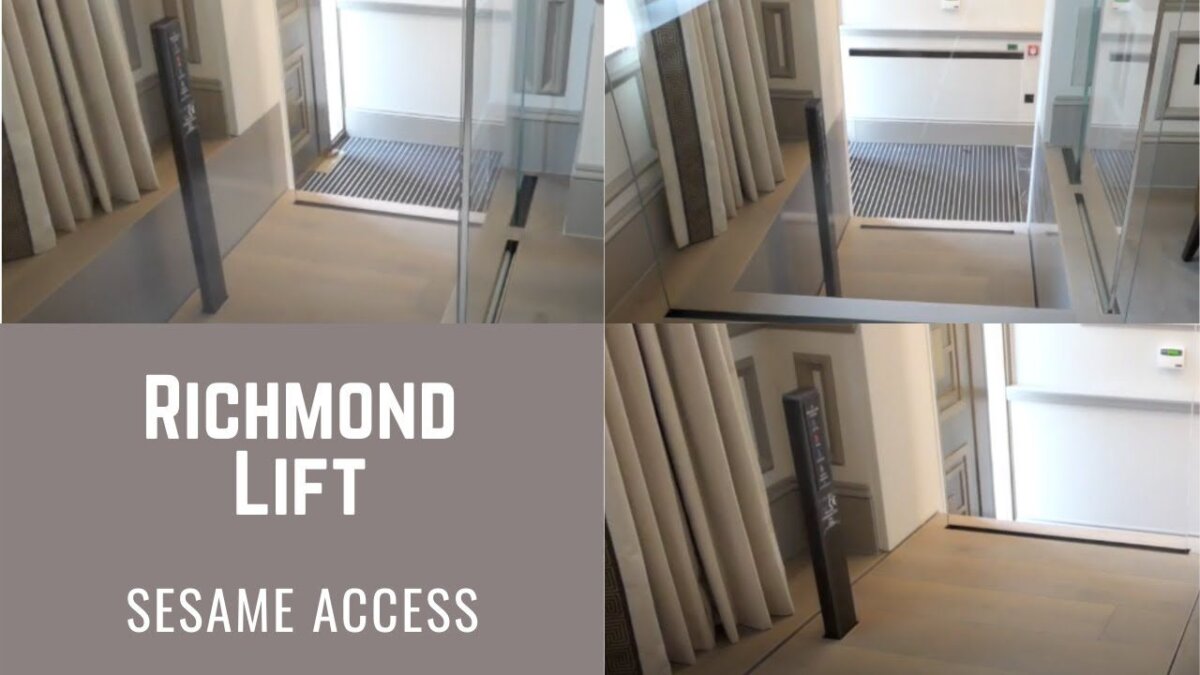

The same coordination discipline applies across all Sesame products, such as the Westminster Equality Act Lift, Wellington Lift, Richmond Rising Platform Lift

Each system is manufactured to millimetre-accurate tolerances, making lifting plan precision essential. Whether installing in a new build or a listed property, correct structural referencing and pre-installation modelling guarantee a smooth, compliant finish.

Frequently Asked Questions (FAQ)

What is a lifting plan?

A drawing and verification document showing how a bespoke lift fits within a building’s structure.

Why are SCSR and SCSC used?

They mark the lift’s riser and centreline to align it with the architectural grid and safety zones.

What is clash detection in lift planning?

It is the digital process of finding conflicts between the lift frame, site steels, and other building elements before construction begins.

What tolerances are typical?

Between 8 mm and 20 mm depending on site constraints and European lift standards.

How do I begin a project?

Book a consultation with our Project Management Team to receive a coordinated lifting plan tailored to your site.