Key Takeaways

-

Hidden staircase lift projects require a structured workflow starting with a clear call, rapid site survey and immediate 3D modelling.

-

Reviewing the 3D model enables engineers to avoid basement doors, fire escape paths, pipework and structural constraints before any drawing is produced.

-

Sesame Access selects the best solution from a range of 30+ bespoke products, including the Wellington Lift, Knightsbridge Stair Lift and Cambridge Part M Lift, ensuring a perfect fit even in challenging environments.

-

Clients receive a technical feasibility review within 24 hours, enabling quick decisions.

-

Once approved, Sesame prepares planning-application-ready drawings and structural coordination packages.

Introduction

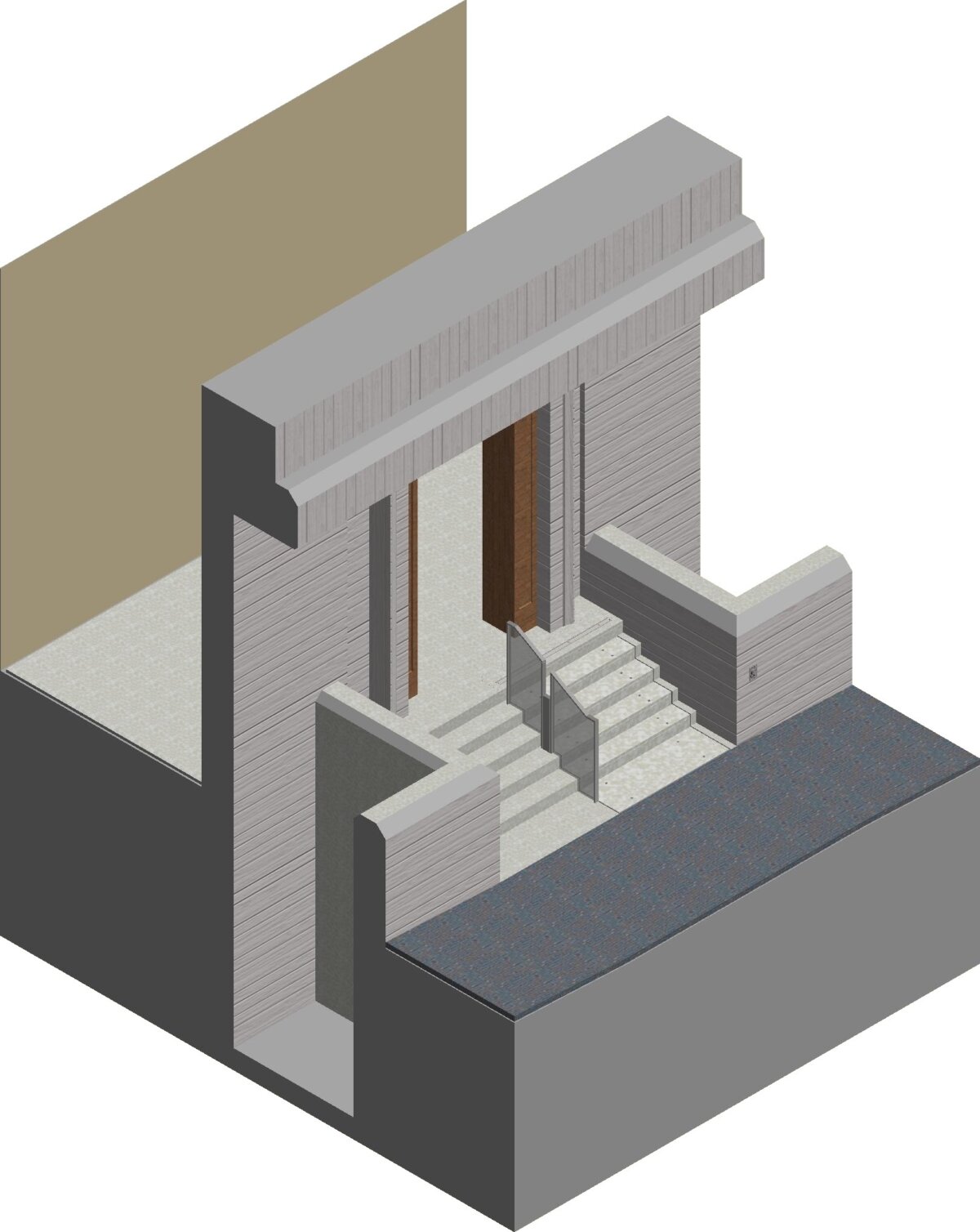

Architects and contractors often face complex accessibility challenges: uneven stone steps, low headroom, sloping floors, tight basements, fire escape routes and services that cannot be moved. These constraints make it difficult to integrate an accessibility lift without disturbing the original architecture.

Sesame Access solves this by following a consistent process: a fast site survey, precise 3D modelling, careful review of obstructions and selection of a bespoke lift system designed to fit the existing structure. This results in planning-ready documentation delivered within 24 hours of survey data being received.

Stage 1: Initial Call and Project Brief

Every project begins with a technical call where the staircase geometry, access needs and any restrictions are discussed. Clients often highlight features such as:

-

A basement door directly under the staircase

-

A required fire escape route below

-

Existing pipework or services that cannot be relocated

-

Heritage or conservation constraints

-

Unusual tread depths, sloping steps or non-standard riser heights

This early conversation ensures the site survey is targeted and efficient.

Stage 2: Rapid Site Survey

A surveyor attends site to capture the exact staircase dimensions. Key measurements typically include:

-

Step widths (often ranging between 1200 mm and 1650 mm)

-

Tread depths and riser heights (including irregularities)

-

Distance from top step riser to basement wall (for example 1400–1500 mm)

-

Available pit depth (commonly between 900–950 mm in constrained sites)

-

Clearance required around handrails (minimum 300 mm to avoid crush zones)

-

Height of door heads beneath the staircase

-

Any pipes or mechanical equipment passing under the treads

Laser measurements and photographs are collected to give the engineering team complete visibility.

Stage 3: Creating the 3D Model

The engineering team immediately converts the survey data into a 3D model. This is a critical step because it shows the staircase exactly as built, including any irregularities that could affect lift performance.

The 3D model allows Sesame to:

-

Test straight-route access versus 90° turning access

-

Check for collisions with doors beneath the staircase

-

Confirm fire escape routes remain unaffected

-

Avoid pipes, ducting and electrical services

-

Understand space constraints for platform sizes between 1200 mm and 1400 mm

-

Model step correction and ensure risers are level and safe

-

Validate the pit depth and mechanical envelope

This modelling process aligns with the guidance shared in the Knowledge Hub articles 3D Modelling in Lift Design and Designing a Bespoke Heritage Staircase Lift.

Stage 4: Assessing Feasibility and Avoiding Obstructions

The 3D review focuses on four critical obstructions:

1. Basement Doors

The model confirms whether the lift and wheel stops clear the door head, ensuring no collision risks.

2. Fire Escape Routes

Engineers verify that egress paths remain unobstructed both when the lift is stowed and when deployed.

3. Pipework Beneath the Staircase

Clearances of 50–200 mm can be essential to avoid pipe clashes. Where necessary, components are reshaped or offset.

4. Irregular Steps and Riser Heights

Step correction ensures that all steps are level, the risers are even and the lift sits on a safe, predictable plane.

This technical review is essential for preventing additional structural works and maintaining original architectural features.

Stage 5: Selecting the Correct Product

Sesame Access has more than 30 bespoke lift systems, allowing the team to match the staircase to the correct product without forcing architectural compromises.

Common solutions for challenging staircases include:

-

Wellington Lift – Ideal for deep rises and heritage sites where minimal intervention is essential.

-

Knightsbridge Stair Lift – Suitable for narrow staircases benefiting from straight-route access.

-

Cambridge Part M Lift – Often used where compliance with accessibility regulations and restricted geometry must be balanced.

The engineering team reviews platform length options (typically 1200 mm, 1300 mm or 1400 mm) and determines whether straight-route or 90° access is more appropriate. Optimising platform rotation ensures that most wheelchair users can enter smoothly, even in restricted spaces.

Technical Specifications Table (Example)

| Feature | Wellington Lift | Knightsbridge Stair Lift | Cambridge Part M Lift |

|---|---|---|---|

| Typical Platform Length | 1250 - 1400 mm + | 1400 mm + | 1612 mm |

| Typical Pit Depth | 900–950 mm | 1400mm | 650mm |

| Rise Capability | Up to 1 m | Up to 1 m | Up to 3 m |

| Best Use Case | Heritage deep-rise | Hidden controls on the lift table | Part M compliance |

Stage 6: Client Presentation Within 24 Hours

Within 24 hours of receiving the survey data, Sesame provides:

-

Full 3D model review

-

Recommended lift configuration

-

Explanation of how doors, pipes and fire routes are avoided

-

Summary of any required step correction

-

Straight-route vs 90° access justification

-

Technical feasibility report

This fast turnaround allows architects and contractors to progress the project immediately.

Stage 7: Planning Drawings and Structural Coordination

Once the lift choice is approved, Sesame prepares:

-

Planning-ready GA drawings

-

Pit sections and construction notes

-

Structural loading information

-

Cable routes, drainage points and mechanical clearances

-

Coordination documents for consultants and contractors

These drawings are suitable for planning applications, listed building submissions and structural calculations.

Frequently Asked Questions (FAQ)

How quickly can a feasibility review be completed?

Within 24 hours of receiving the survey data.

Can the lift avoid pipes, doors and fire escape routes?

Yes. The 3D model ensures all obstructions are identified and avoided.

Do you correct uneven steps?

Yes. Step correction is modelled where riser heights vary or where safety could be affected.

How do I know whether straight-route or 90° access is best?

Our engineers compare platform rotation, usable width and obstacle clearance to recommend the optimal solution.

Are planning drawings included?

Yes. Planning-application-ready drawings and structural coordination documents are provided.

Call to Action

To discuss your project with an expert, book a meeting with one of our Project Managers:

https://www.sesameaccess.com/book-a-meeting