Key Takeaways

-

Heritage entrances often require access solutions that leave the visible architecture unchanged

-

Pavement ownership depth and public safety constraints frequently rule out standard lift products

-

Manual, positively locked systems are often safer and more approvable than automated alternatives

-

Bespoke engineering allows access to be delivered without compromising listed fabric

Introduction: Why Invisible Access Requires Bespoke Engineering

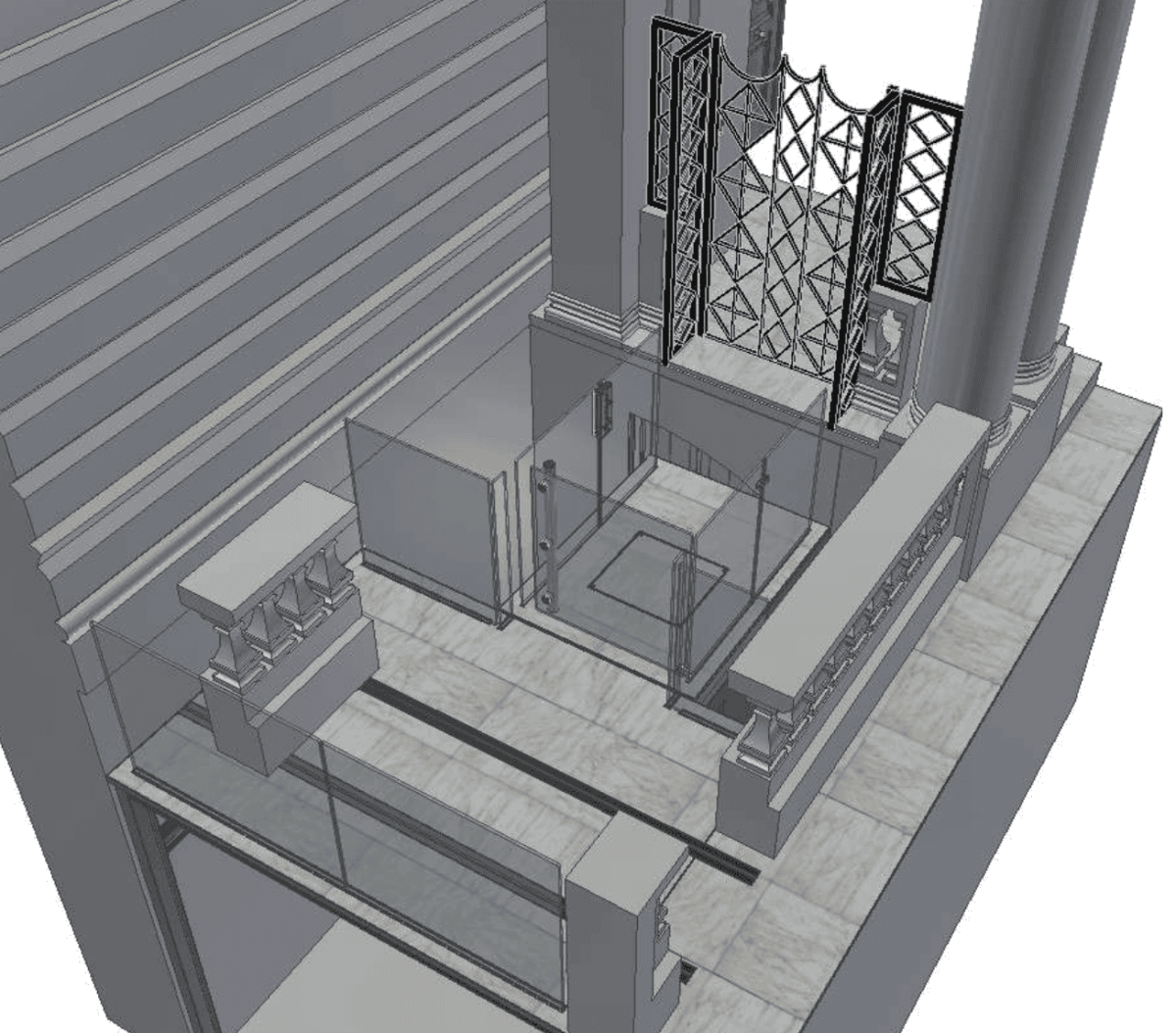

Designing step-free access for heritage pavement entrances is not a case of selecting a product and fitting it into place. In listed and conservation-sensitive environments, the entrance appearance is effectively fixed. The engineering must adapt around it.

Standard accessibility products assume that visible changes are acceptable. In heritage contexts, this assumption fails. Stone balustrades, pavement thresholds, and boundary lines often cannot be altered, moved, or visually interrupted.

As discussed during early feasibility review, the brief is often explicit:

“What they wanted is a solution that looks as it is today.”

This constraint-driven reality is why invisible access solutions demand bespoke engineering rather than off-the-shelf systems. The work is engineered for the real world, accounting for debris, public interaction, maintenance access, and long-term reliability, not idealised renderings.

The Core Problem: Access Without Visual Change

Many heritage entrances are defined by solid stone balustrades running directly along public pavements. These elements typically form both a visual boundary and a legal ownership line. Excavation depth is often limited to approximately 200–300mm below pavement level, immediately ruling out many recessed or track-based systems.

At the same time, conservation requirements usually prohibit visible gates, rails, pivots, or gaps that would alter the original appearance. Even small visual compromises can result in planning refusal.

The challenge is not whether access can be provided, but how it can be provided without introducing visual, legal, or safety conflicts.

Exploring Concept Options: Sliding, Swinging, or Lowering?

Sliding Concepts and the Reality of Pavement Environments

Sliding wall or balustrade concepts are often proposed early because they appear visually clean. However, real-world engineering quickly exposes their weaknesses in public pavements.

Debris accumulation, tolerance sensitivity, and long-term seizure risk are recurring concerns. As noted during review:

“The biggest problem you're going to have here is for debris getting in those tracks.”

In environments where dirt, grit, water, and litter are unavoidable, track-based systems demand suspended-load designs, generous clearances, and ongoing maintenance access. Without this, reliability and safety degrade over time.

Swing Gate Replication and Visual Impact

Hinged solutions can be mechanically simpler and safer, particularly when manually operated. However, even a manual swing introduces visible pivot points, clearances, and movement lines that can alter the appearance of historic stonework.

As discussed internally:

“If you turn that into a swing gate, how much that's going to change from what it looks like now.”

Where visual continuity is paramount, swing systems are often rejected unless they can be disguised using replica materials and concealed hardware.

Vertical or Retracting Approaches and Excavation Limits

Lowering elements can remove lateral movement risks but typically require deeper excavation. In pavement-fronting entrances, this is frequently impossible due to ownership boundaries.

One feasibility comparison summarised the trade-off clearly:

“You’re only going to need 300mm below pavement level on this option.”

This depth constraint is a key driver toward internal frameworks and concealed platforms rather than external or pavement-based mechanisms.

How Bespoke Lift Engineering Resolves These Conflicts

Bespoke engineering allows the access solution to be designed around fixed constraints rather than forcing the building to adapt to a standard product.

Typical strategies include:

-

Lightweight composite replicas replacing original stone elements

-

Internal steel frameworks isolated from visible heritage fabric

-

Manual operation with positive locking to reduce crush risk

-

Maintenance access entirely within private ownership lines

This approach reflects the principles outlined in Sesame Access’s work on

precision lift engineering, where tolerances, load paths, and serviceability are treated as primary design inputs.

Solutions such as the Westminster Equality Act Lift, Whitehall DDA Lift, and Windsor Lift demonstrate how concealed platforms and internal frameworks can deliver compliant access without visual disruption.

For more complex geometries, fully bespoke systems like the Bespoke Lift or Traversing Lift allow movement paths to be tailored around heritage constraints.

Engineering Decision Framework: How Solutions Are Selected

When evaluating heritage pavement entrances, Sesame Access applies a constraints-first engineering decision process.

The sequence typically follows:

-

Pavement ownership depth assessment

Where ownership is limited to approximately 300mm, all recessed and track-based pavement systems are excluded. -

Public liability and crush hazard exposure

In unattended or publicly accessible areas, manual systems are favoured when hazards cannot be physically guarded. -

Maintenance access routes

Any system requiring external pavement access for servicing is ruled out. -

Visual continuity and conservation requirements

Original stone fabric is retained in situ wherever possible, with replica composites used for moving elements.

This framework reflects lessons drawn from long-term reviews such as the

engineering review of Wellington, Richmond, and Cavendish lift systems.

Solution Selection Matrix

| Your Constraint | Eliminates These Options | Directs Toward |

|---|---|---|

| No visible change permitted | Standard platform lifts | Bespoke concealed platforms |

| Pavement ownership <400mm | Recessed track systems | Internal frameworks |

| Manual operation mandated | Automated mechanisms | Positive-lock manual systems |

| Listed building constraints | Surface-mounted rails | Replica composite elements |

The Maintenance–Safety Paradox

A common misconception is that automated systems are inherently safer or more modern. In public heritage environments, the opposite is often true.

Tighter tolerances improve aesthetics but increase the risk of seizure when debris enters moving interfaces. Manual systems with positive locking often pass safety review faster because they reduce automation-related crush hazards and simplify compliance.

This paradox is frequently encountered when sliding concepts are proposed without considering long-term pavement conditions.

Common Specification Mistakes

Mistake 1: Specifying flush threshold access without confirming pavement ownership

Most councils retain ownership at depths of only 200–300mm, making recessed systems unviable.

Mistake 2: Assuming automation improves accessibility

In public zones, manual systems often reduce risk and gain approval faster.

Mistake 3: Requesting like-for-like stone movement

Conservation officers typically require original stone to remain fixed, making composite replication the practical solution.

Product Integration Summary

| Requirement | Suitable Sesame Access Approach |

|---|---|

| Invisible appearance when closed | Bespoke concealed lift systems |

| Minimal excavation depth | Internal low-profile frameworks |

| Manual safety preference | Positively locked mechanisms |

| Heritage planning sensitivity | Replica composite finishes |

Frequently Asked Questions

Can original stone balustrades be moved?

In most heritage settings, original stone must remain fixed. Lightweight replicas are used for any moving elements.

Are manual systems compliant with accessibility legislation?

Yes. Manual systems can meet Equality Act requirements when correctly engineered and assessed.

How is debris managed in concealed mechanisms?

Designs avoid exposed pavement tracks and provide internal access for inspection and cleaning.

Is bespoke always more expensive?

Not necessarily. Avoiding redesign, planning delays, and compliance issues often reduces overall project risk.

When should feasibility discussions start?

Ideally before planning submission, when layout assumptions can still be corrected.

Next Steps

If you are dealing with a heritage or pavement-level entrance where visible change is not an option, an early engineering discussion can clarify feasibility and risk.

Book a Teams meeting with a Sesame Access Project Manager here:

https://www.sesameaccess.com/book-a-meeting