Key Takeaways

- A liftway (shaft/hoistway/runway) is the travel space the platform moves within, not the platform itself.

- EN 81-41 is scoped to lifts with enclosed liftways only, so partially or non-enclosed liftways are outside EN 81-41 scope.

- BS 6440 and ASME A18.1 explicitly address non-enclosed and partially enclosed liftway concepts, using guarding and access-control strategies rather than relying on a full shaft.

- Where a harmonised standard does not apply, European compliance must be engineered through a structured risk-based route such as Machinery Directive Annex VIII, supported by a technical file and verification.

- Sesame Access specialises in assessing liftway type first, then combining relevant safety requirements across standards into a defensible compliance strategy for the EU and international projects.

- Toe/roll-off guarding has strict limitations in BS 6440 and must not be misrepresented as suitable for standing users, as discussed in Roll-off guards and standing users.

Introduction

Standards compliance for platform lifts often fails for one simple reason: the liftway architecture is not defined clearly at the start.

A supplier may say a lift is “EN 81-41 compliant”, but EN 81-41’s scope is built around an enclosed liftway safety model. If the project is partially enclosed or open to surrounding space, EN 81-41 cannot be claimed as fully applicable because the liftway is outside the standard’s scope boundary.

This Knowledge Hub page starts with definitions, then maps the right compliance route for each liftway type, including the practical method Sesame Access uses to deliver compliant open liftways under a structured risk-based approach such as Machinery Directive Annex VIII.

If you also need a guide to how UK-built lifts can conform where EN 81-41 is applicable, see UK-built lifts for the European market conforming to EN 81-41.

Liftway Definitions First

What is a liftway, shaft, hoistway, or runway?

A liftway (sometimes called a shaft, hoistway, or runway depending on the standard and region) is the travel space the moving platform travels within. It is not the platform itself.

Defining the liftway type is the fastest way to decide which standards can genuinely apply.

What is a fully enclosed liftway?

A fully enclosed liftway means the full travel path is continuously surrounded by an enclosure that forms a barrier around the moving parts and travel zone. Access is controlled through defined entrances such as doors or gates rather than open sides.

This is the safety architecture assumed by EN 81-41.

What is a partially enclosed liftway?

A partially enclosed liftway means some parts of the travel path are guarded or enclosed, but the liftway is not continuously enclosed on all sides for the full travel height.

This category is explicitly recognised in ASME A18.1 through partial runway enclosure concepts, where safety is achieved through defined guarding and access control rather than a full shaft.

What is a non-enclosed liftway?

A non-enclosed liftway means one or more sides of the travel path are open to surrounding architectural space.

This configuration can be safe, but it requires the correct safety architecture: guarding strategy, access control, interlocks, usage assumptions, and documented risk reduction measures. In the UK, BS 6440 is often the starting point for these concepts, and in the USA ASME A18.1 explicitly addresses unenclosed runway models.

EN 81-41 Scope: Why “Enclosed Liftway” is a Boundary Condition

Can an open or partially enclosed lift claim full EN 81-41 compliance?

If the liftway is partially enclosed or non-enclosed, it is outside EN 81-41 scope because EN 81-41 is scoped to lifts with enclosed liftways.

A common point of confusion is that the carrier may be open while the liftway must be enclosed. EN 81-41’s safety model relies on the liftway enclosure and enclosed entrances as fundamental system elements, not optional add-ons.

This is why a supplier cannot accurately claim full EN 81-41 compliance for a liftway that is open or only partially enclosed. If the liftway is not enclosed, the correct approach is to identify which standards do apply and which engineering conformity route is required.

For practical context on EN 81-41 conformity for UK-built lifts where an enclosed liftway is present, see UK-built lifts for the European market conforming to EN 81-41.

BS 6440 and ASME A18.1: Standards That Explicitly Address Open Concepts

How does BS 6440 support non-enclosed and partially enclosed liftways?

BS 6440 is a UK platform lift standard that explicitly illustrates and acknowledges non-enclosed liftway arrangements and uses low speed plus guarding strategy to manage risk in open concepts.

One important example is the guarding breakpoint at 1000 mm travel, which changes the barrier strategy and is often central to design decisions.

For real-world implications around guarding and user behaviour, see Roll-off guards and standing users.

How does ASME A18.1 support non-enclosed and partially enclosed runway models?

ASME A18.1 builds safety around runway categories, including enclosed, partial, and unenclosed runway configurations. It uses guarding, runway doors, and interlocks to control access rather than requiring a full shaft everywhere.

This is why US-facing projects, including concepts similar to the Seattle ADA Lift, can remain safe with an open architectural intent when the correct runway protection and access control strategy is engineered.

Common Misconceptions That Cause Compliance Failures

Three misconceptions that lead to incorrect “compliance” claims

Misconception 1: Any European platform lift can be EN 81-41 compliant.

Reality: EN 81-41 is scoped to enclosed liftways. If the liftway is not enclosed, EN 81-41 does not apply as a full compliance claim.

Misconception 2: If the platform is open, EN 81-41 must not apply.

Reality: The platform/carrier may be open, but the liftway must be enclosed for EN 81-41 to apply.

Misconception 3: Open liftways are inherently non-compliant in Europe.

Reality: Open and partially enclosed liftways can be compliant, but they must be engineered via the correct route, typically involving a structured risk assessment and technical file approach such as Machinery Directive Annex VIII when no harmonised standard covers the exact liftway concept.

Which Standard Applies to Your Project?

A simple decision framework for architects and consultants

Question 1: Is the liftway fully enclosed for the full travel height, with controlled entrances?

If yes, EN 81-41 may apply depending on the full scope constraints and design details. Start with EN 81-41 conformity guidance.

Question 2: Is the liftway partially enclosed or non-enclosed as an architectural concept?

If yes, EN 81-41 scope does not cover the liftway concept. Use an open-liftway appropriate framework such as BS 6440 principles (UK) and consider ASME A18.1 concepts where relevant to the project or jurisdiction.

Question 3: Is the project in the EU or a region where a harmonised standard does not cover the open liftway arrangement?

If yes, a Machinery Directive Annex VIII style route is often required, supported by a structured risk assessment, safety requirements mapping, verification, and a technical file.

Problem: Open Liftways Often Sit Outside Harmonised Standard Scope

Why do open liftways create a compliance gap in Europe?

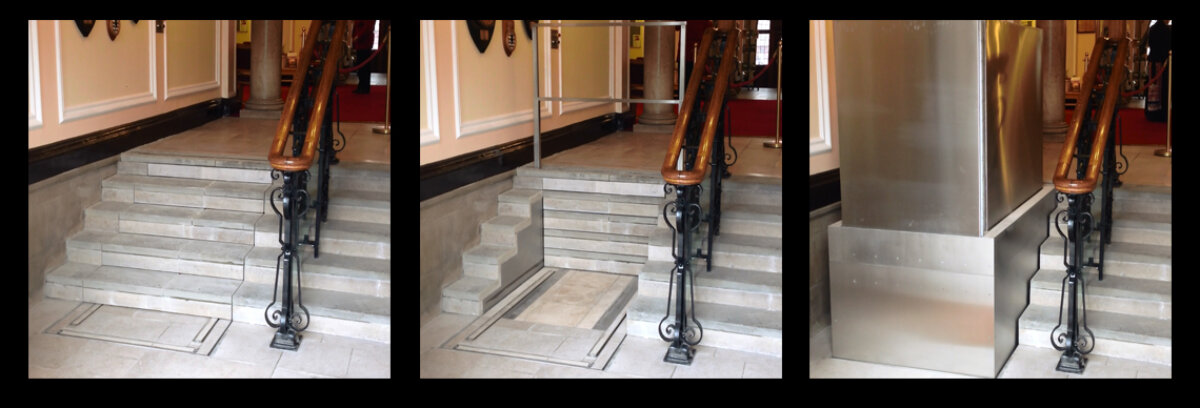

Open and partially enclosed liftways can be a deliberate architectural choice, especially in heritage refurbishments, public realm upgrades, and projects where a full shaft would compromise layout or aesthetics.

The challenge is that EN 81-41 is built around an enclosed liftway safety model, so open liftway projects require a different conformity path.

This is where Sesame Access’s engineering approach becomes valuable: define the liftway type first, then map the correct compliance route, then document the design with a robust technical file.

Solution: Machinery Directive Annex VIII and Risk-Based Engineering

What does Annex VIII mean in practice for platform lifts?

When a lift concept falls outside the scope of a harmonised standard such as EN 81-41, the compliance route shifts to a structured machinery conformity approach.

In practical terms, Annex VIII style compliance involves:

- a full risk assessment methodology aligned with established machinery safety principles

- hazard identification for crushing, shearing, fall risk, misuse, emergency operation, and maintenance access

- justification of protective measures and safeguards

- verification tests and documented evidence

- a structured technical file to support the Declaration of Conformity

This is how a bespoke lift can be safe and compliant when the liftway concept is open and local standards do not fully cover that configuration.

How Sesame Access Engineers Compliant Open Liftways Worldwide

What Sesame Access does differently

Sesame Access starts every project by defining the liftway architecture, then building the compliance strategy around what is actually in scope.

This process typically includes:

- confirming whether EN 81-41 can apply by scope, not assumption

- mapping BS 6440 and ASME A18.1 concepts where open or partial liftways are present

- designing guarding strategy, access control, and interlocks appropriate to the liftway type

- building a technical file aligned to an Annex VIII style internal checks route where required

- supporting project teams through approvals, documentation, and safety sign-off expectations across jurisdictions

This approach is used across bespoke solutions like the Bespoke Lift and architectural integrations such as the Traversing Lift, and it also supports public-facing compliance needs across projects similar to the Westminster Equality Act Lift and Whitehall DDA Lift.

Product Integration Summary

How liftway type influences product strategy and compliance route

Sesame solution |

Typical liftway concept |

Common compliance route |

Non-enclosed or partially enclosed by architectural intent |

Annex VIII style technical file + relevant standard mapping |

|

Open architectural travel path |

Risk-based safeguarding and access control strategy |

|

Guarded open concept |

BS 6440-driven guarding logic where applicable |

|

Unenclosed runway concept |

ASME A18.1 runway protection and interlocks logic |

|

Heritage-sensitive, often open/partial constraints |

Annex VIII style justification + engineered safeguarding |

Related reading for guarding limits and user assumptions: Roll-off guards and standing users.

Related reading for EN 81-41 applicability and conformity pathway: UK-built lifts conforming to EN 81-41.

International Scope and Alternative Compliance Routes

Where EN 81-41 does not apply due to non-enclosed or partially enclosed liftway architecture, compliance may require structured risk-based conformity approaches. For an example of a formal variance pathway under a prescriptive North American standard, see ASME A18.1 Permanent Variance: Docket 24-V-358 Analysis. Canadian guarding and equivalency interpretation under CSA B355 and TSSA review is discussed in Roll-Off Guard Canada – CSA B355 & TSSA Approval Guide. For additional context on US AHJ engagement under ASME A18.1, see UK Platform Lifts USA AHJ ASME A18.1 Guide.

Frequently Asked Questions (FAQ)

What is the non-enclosed liftway definition in simple terms?

A non-enclosed liftway is a travel path where one or more sides are open to surrounding space. Safety must be managed through guarding, access control and documented safeguards rather than a full shaft.

What is the difference between partially enclosed and fully enclosed liftways?

A partially enclosed liftway has guarding on some sections but not continuous enclosure on all sides for the full travel height. A fully enclosed liftway is continuously enclosed for the full travel height with controlled entrances.

Can a supplier claim EN 81-41 compliance if the liftway is open or partially enclosed?

No. EN 81-41 is scoped to enclosed liftways. If the liftway is open or partially enclosed, it is outside EN 81-41 scope as a full compliance claim.

Does an open liftway automatically mean non-compliance in Europe?

No. It means a different compliance route is needed. Where a harmonised standard does not cover the liftway concept, a Machinery Directive Annex VIII style route with a risk assessment and technical file is typically required.

Where can I read about toe guards, roll-off guards and standing user risk?

See Roll-off guards and standing users.

How do I decide whether EN 81-41 is relevant to my project?

Start with the liftway definition. If it is fully enclosed, EN 81-41 may apply. If it is partially or non-enclosed, EN 81-41 scope does not apply as a full compliance claim. See EN 81-41 conformity guidance for UK-built lifts.

What should I do if my authority asks for “the standard” but my design is open?

Document the liftway type, then present the engineered compliance route with a structured risk assessment and technical file, typically aligned to an Annex VIII style approach, supported by relevant safety principles from standards that explicitly cover open concepts.

Call to Action

If you are designing a non-enclosed or partially enclosed liftway and need a defensible compliance route for Europe or an international project, book a Teams meeting with one of our Project Managers:

Book a Teams Meeting with Sesame Access