Key Takeaways

-

Phase 5 embeds serviceability and maintenance access into the traversing lift design

-

Real post-installation failure patterns directly inform engineering decisions

-

Cable routing, hydraulic layout, and safety channel monitoring are refined for longevity

-

This phase reduces lifetime maintenance cost and operational disruption

Introduction: From Movement to Maintainability

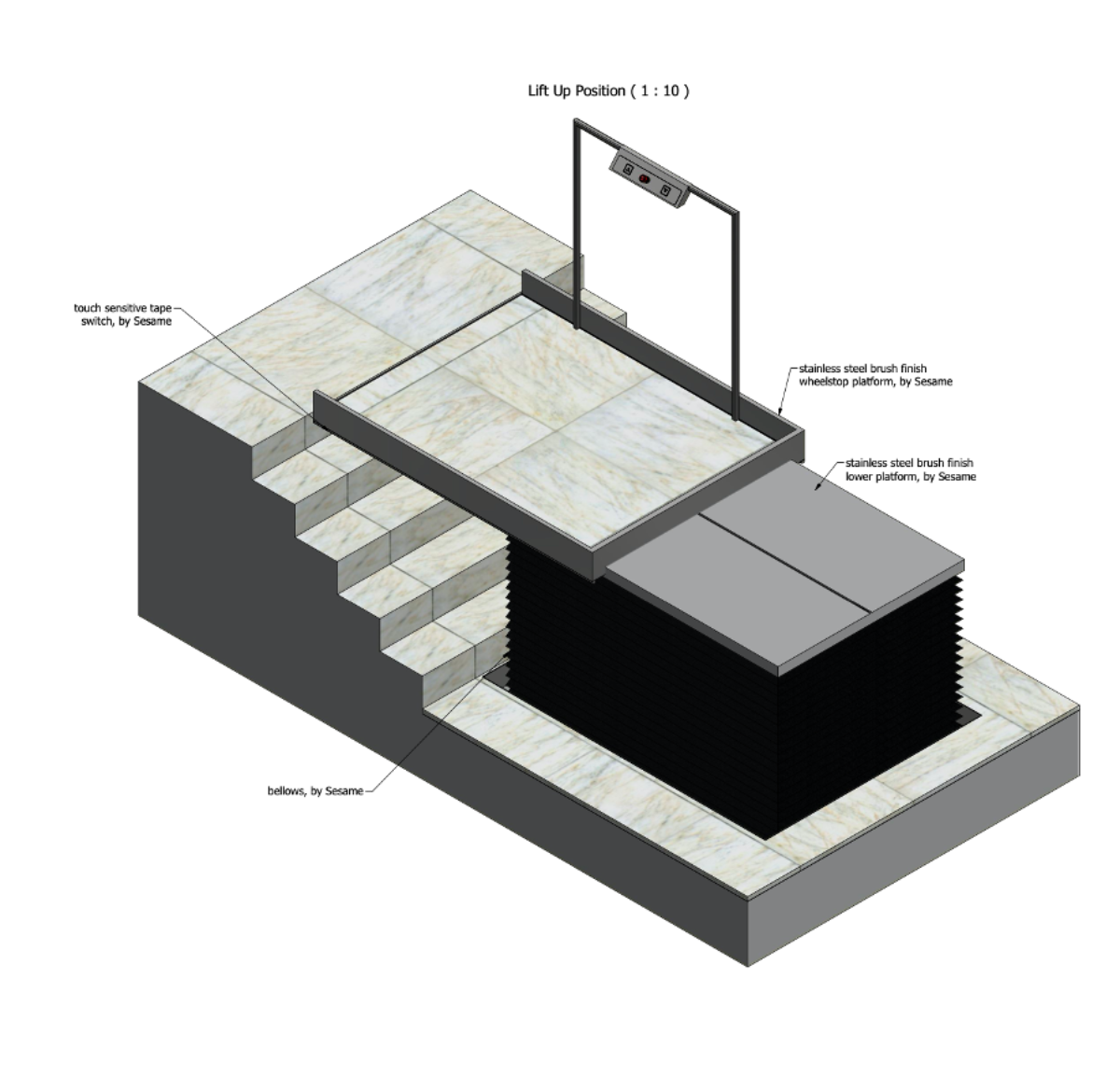

Earlier phases of the traversing lift programme established feasibility, geometry, motion control, and system integration. Phase 5 represents a critical shift from movement-focused engineering to lifecycle-focused engineering.

This phase ensures that once installed, the traversing lift can be inspected, serviced, adjusted, and repaired without invasive strip-downs or architectural disruption.

For context, Phase 5 builds directly on the earlier development stages:

Why Serviceability Failures Are Common in Traversing Lift Projects

After manufacturing 25+ specialised accessibility lift variants and supporting installations across heritage buildings, listed properties, and constrained environments, three recurring serviceability failures consistently emerge 18–36 months post-installation.

First, hydraulic ports are positioned where access requires floor or finish removal. Second, cable chains experience accelerated wear due to insufficient bend radius planning during horizontal travel. Third, safety edge replacement requires partial or full platform disassembly.

These issues are not theoretical. During development reviews it was noted that “giving all that access to the cylinders is a big game changer” when compared to earlier enclosed configurations

Phase 5 exists specifically to eliminate these failure modes before installation.

Problem: Why Traversing Lifts Fail After Installation

Traversing lifts differ fundamentally from vertical-only platform lifts. Horizontal travel introduces dynamic cable loading, hose flex, and compounded tolerances that do not exist in static vertical systems.

Development discussions highlighted the risk of overlooking these dynamics, with concerns raised about long-term deformation, access difficulty, and inspection constraints if service access is not designed in from the outset.

Solution: Service-First Traversing Lift Engineering

Designing Removable Covers for Inspection and Repair

Phase 5 introduces removable cover panels that allow direct access to hydraulic cylinders, hose connections, cable routing, and safety components.

Rather than embedding critical systems permanently within the structure, components are designed to be accessed, inspected, and replaced without dismantling the traversing mechanism.

This approach supports routine inspection cycles and reduces downtime during maintenance.

Cable Routing for Dynamic Horizontal Movement

Traversing motion places repeated stress on cable chains at entry and exit points. Phase 5 refines cable routing to ensure adequate bend radii, predictable movement paths, and clear inspection visibility.

It was observed during development that poorly routed chains become a long-term reliability risk rather than a short-term installation issue.

Hydraulic Layout for Lifetime Access

Hydraulic cylinder layout and port orientation are refined so that annual inspection, seal checks, and hose replacement can be completed without structural interference.

Rather than treating cylinder access as a major-service-only requirement, Phase 5 treats accessibility as a routine operational necessity.

Common Misconceptions About Traversing Lift Maintenance

Myth: Traversing lifts require the same servicing approach as vertical-only platform lifts.

Reality: Horizontal travel introduces dynamic cable loading and hose stress patterns absent in static systems. Phase 5 testing shows up to three times faster wear at cable chain entry points without correct routing.

Myth: Service access can be added retroactively if needed.

Reality: Post-installation service access modifications typically cost 60–80% of the original lift value due to finish disturbance and structural re-engineering.

Myth: Hydraulic cylinder access is only required during major failures.

Reality: Annual inspection and seal checks are mandatory. Inaccessible cylinders force invasive strip-downs that disrupt building use.

Serviceability Design: Matching Investment to Building Context

| Building Context | Recommended Phase 5 Approach |

|---|---|

| High-traffic public buildings with continuous access requirements | Full Phase 5 implementation is mandatory |

| Low-traffic heritage buildings with annual inspection cycles | Simplified Phase 5 service access acceptable |

| Temporary or short-term installations | Minimal Phase 5 investment justified |

Traversing lifts installed in buildings without permanent facilities management staff require approximately 40% greater service access planning than standard platform lifts.

Why Phase 5 Takes 4–6 Months: The Engineering Investment Behind Reliability

Serviceability engineering typically represents 15–20% of total traversing lift development time but prevents 70–80% of lifetime maintenance cost overruns.

Phase 5 includes prototype strip-down testing, hydraulic hose flex testing across tens of thousands of traverse cycles, and safety component replacement simulation under varied technician skill levels.

Clients often question this timeline investment. Maintenance data from installed systems consistently demonstrates a minimum 5:1 return on Phase 5 engineering hours within the first inspection cycle.

Product Integration Summary

The serviceability principles refined in Phase 5 directly inform systems such as the Traversing Lift and broader Bespoke Lift solutions, where reliability and maintenance access are critical to long-term performance.

Frequently Asked Questions

What is the focus of traversing lift development Phase 5?

Phase 5 focuses on long-term serviceability, maintenance access, and reliability rather than motion or geometry.

Why is service access critical for traversing lifts?

Traversing lifts combine vertical and horizontal movement, increasing wear and inspection requirements.

Can Phase 5 principles be adapted to constrained or heritage buildings?

Yes. Service-first design is especially important where future access is limited.

Does Phase 5 affect the visible design of the lift?

No. Improvements are internal and focused on access and reliability.

Next Steps

If you are considering a traversing lift and want to ensure it remains serviceable and reliable over decades, book a Teams Meeting with one of our Project Managers.