Key Takeaways

-

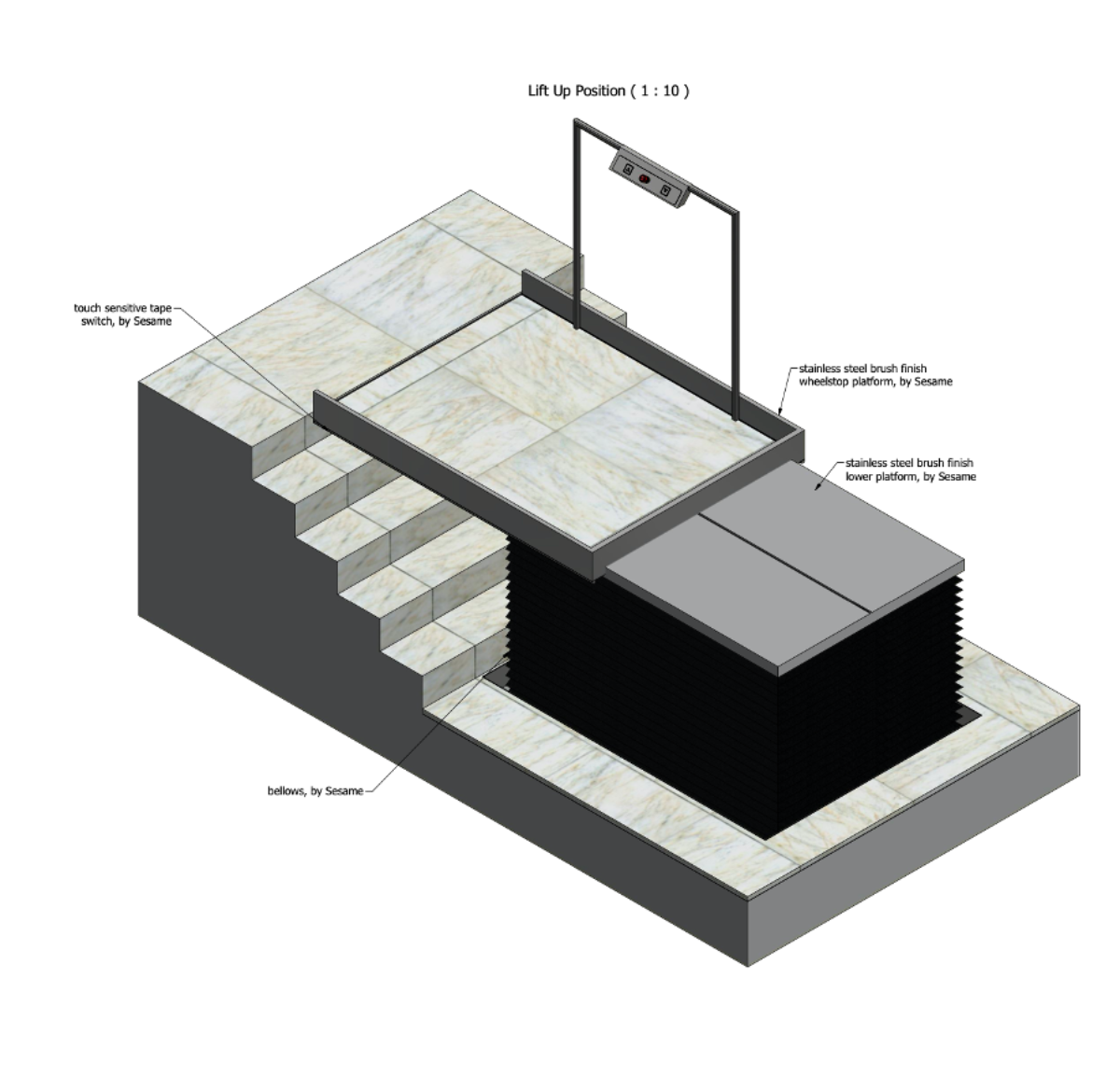

Phase 6 is the final technical checkpoint before the traversing lift prototype is ordered and manufactured.

-

The objective is to eliminate build-risk by locking structural, hydraulic, wiring, safety, and service decisions into a single manufacture-ready design.

-

Phase 6 improves reliability by validating real-world constraints such as manual adjustment limits, thread engagement, cable routing collisions, and access for future maintenance.

-

This phase reflects maintenance-led engineering, not just “final drawings”.

Introduction: What Makes Phase 6 Different

Phase 6 is the moment a development programme becomes a manufacturing commitment.

Earlier phases prove the concept, refine the envelope, and de-risk integration. Phase 6 is where the team removes the final unknowns that cause cost, delays, or reliability issues once metal is cut.

This page is written to help architects, access consultants, project managers, and engineers understand what “lock-in before manufacture” actually means in practice.

How Phases 1–5 Led to Phase 6

Phase 6 only works because the earlier phases did their job.

-

Phase 1 established the traversing lift concept and why it exists

https://www.sesameaccess.com/knowledge-hub/traversing-lift-development-phase-1 -

Phase 2 validated geometry, movement strategy, and constraints

https://www.sesameaccess.com/knowledge-hub/traversing-lift-development-phase-2 -

Phase 3 refined structural behaviour, guidance, and platform stability

https://www.sesameaccess.com/knowledge-hub/traversing-lift-development-phase-3 -

Phase 4 resolved interfaces, guarding, and integration sequencing

https://www.sesameaccess.com/knowledge-hub/traversing-lift-development-phase-4 -

Phase 5 completed the pre-lock risk burn-down and detail refinement

https://www.sesameaccess.com/knowledge-hub/traversing-lift-development-phase-5

Phase 6 builds on all of the above and commits the final design for prototype manufacture.

Engineering Decision Archive

This article documents real engineering decisions made during Phase 6 review in early 2026.

The technical choices described here reflect Sesame Access’s accumulated knowledge in constrained-space accessibility engineering, where reliability failures usually come from practical oversights: tolerance stacking, access assumptions, routing collisions, or safety logic that is correct on paper but awkward in the field.

Phase 6 exists to surface those issues before the prototype is manufactured.

Problem–Solution: What Phase 6 Is Designed to Prevent

Phase 6 targets predictable “prototype issues” that appear late if they are not deliberately hunted.

These include:

-

insufficient thread engagement and unpredictable adjustment on site

-

fixings that work in CAD but loosen, distort, or become unserviceable in reality

-

cable and hose routes that interfere with moving arms, cylinders, or covers

-

maintenance access that requires partial disassembly

-

safety functions that cannot be separated cleanly across motions and resets

-

dust and water pathways that increase long-term failure risk

Technical Constraint Logic: Why Specific Trade-offs Were Locked In

Manual adjustment limits and thread engagement

Phase 6 locked in the adjustment method so installers do not need excessive manual winding.

The aim is controlled, repeatable site adjustment with defined thread engagement rather than “adjust until it looks right”.

“We don’t want to wind that post manually more than three times.”

“We calculated the amount of threads being on that bolt… it’s exactly 15 millimetres.”

This is not just convenience. It reduces variability and improves long-term reliability by preventing over-adjustment and uneven load paths.

Environmental Resilience Markers: Dust and Water Are Designed For

Phase 6 included practical design details that exist purely because real sites are dirty, wet, and unpredictable.

A specific example is the platform cut-out logic intended for dust and water management, which reduces the likelihood of grime accumulation and service issues over time.

“We have a big cut out here… like a keyhole… for the dust removal purposes. All the dust, all the water…”

This kind of detail is often missing from generic lift designs, but it matters hugely in heritage entrances, retail thresholds, and complex refurb environments.

Maintenance-Led Engineering: Service Access Was Treated as a Design Requirement

Phase 6 locked in removable cover and access strategies that allow inspection and service without dismantling the main structure.

This is lifecycle engineering, not prototype theatre.

“Giving all that access, is a big game changer.”

The guiding principle here is simple: if service access is difficult, service won’t happen properly, and reliability suffers. Phase 6 makes the lift maintainable by design.

Why Bespoke Lift Safety Is Often Misunderstood

Many assume safety is mostly software or programming.

In reality, bespoke lift safety depends on physically reliable separation of functions across movement states. A tape switch or interruption must be able to stop one motion without preventing the correct reset or recovery movement.

Phase 6 explicitly addresses that operational logic so the lift can:

-

stop forward motion safely

-

allow controlled retraction/reset behaviour

-

avoid nuisance trips that create unsafe operator workarounds

This is one of the areas where “it complies” is not enough; the system must behave correctly under real use patterns.

When Phase 6 Lock-In Makes Sense (and When It Doesn’t)

Phase 6 lock-in is appropriate when:

-

surveys are complete and critical constraints are confirmed

-

structural assumptions are validated (loads, interfaces, fixing zones)

-

the client route and operational intent are stable

-

the project programme demands a manufacture-ready design freeze

Phase 6 is premature when:

-

the structural load-bearing assumptions remain unknown

-

the architectural route is still changing

-

multiple design routes are still viable and being compared

-

approvals or consents could force major geometry changes

Locking too early increases project risk because it forces later redesign into manufactured constraints rather than into drawings.

Product Integration Summary

Phase 6 decisions were informed by Sesame Access’s wider experience across constrained-space accessibility solutions. Relevant product context includes:

-

Traversing Lift

https://www.sesameaccess.com/lifts/traversing-lift -

Bespoke Lift

https://www.sesameaccess.com/lifts/bespoke-lift -

Westminster Equality Act Lift

https://www.sesameaccess.com/lifts/westminster-equality-act-lift -

Kensington Stairlift

https://www.sesameaccess.com/lifts/kensington-stairlift -

Cavendish Platform Lift

https://www.sesameaccess.com/lifts/cavendish-platform-lift

If you want a comparison table here, the cleanest approach is to compare decision drivers rather than specs:

| Requirement Driver | Typical constrained-space solution | Where Traversing Lift sits |

|---|---|---|

| Need to keep entrance visually clean | https://www.sesameaccess.com/lifts/bespoke-lift | Traversing lift is designed for concealed, engineered integration |

| Tight geometry and limited fixing zones | https://www.sesameaccess.com/lifts/westminster-equality-act-lift | Phase 6 focuses on tolerance control and predictable site adjustment |

| Long-term maintainability in difficult access areas | https://www.sesameaccess.com/lifts/cavendish-platform-lift | Phase 6 prioritises service access as a design requirement |

Common Misconceptions About “Design Freeze”

Misconception 1: Design freeze prevents customisation.

The opposite is true. Locking the core system creates a stable, proven foundation that can then be adapted safely for different buildings without reinventing critical safety and reliability logic.

Misconception 2: Phase 6 is just final drawings.

Phase 6 is about validating operational behaviour under worst-case realities: full extension loads, service access constraints, tolerance stacking, cable collisions, dust/water management, and safe motion separation.

Misconception 3: Safety can be solved later in commissioning.

If safety logic and routing constraints are not locked into the mechanical design, you often end up commissioning around problems instead of eliminating them.

Frequently Asked Questions

What is Phase 6 in traversing lift development?

Phase 6 is the final engineering lock-in stage before Sesame Access orders and manufactures the prototype. It removes remaining build-risk and commits the design.

How is Phase 6 different from Phase 5?

Phase 5 resolves remaining design questions. Phase 6 confirms the final build-ready decisions and makes sure the system is genuinely manufacturable, installable, and serviceable.

Does Phase 6 mean the lift can no longer be adapted to a specific building?

No. Phase 6 locks the core engineering logic so adaptations can be made safely without compromising reliability or safety separation.

What types of projects benefit most from Phase 6 lock-in?

Projects with tight envelopes, complex thresholds, limited fixing zones, or demanding access and maintenance constraints.

Why does Sesame focus so much on service access?

Because service access determines lifecycle reliability. If components can’t be accessed easily, maintenance becomes inconsistent, and failures rise over time.

What is the next step after Phase 6?

Prototype ordering, manufacture, assembly, and validation testing. This is the point where physical testing confirms the Phase 6 decisions.

Next Step: Book a Teams Meeting

If you are assessing whether a traversing lift could work in your building, the most efficient step is a technical review call.

Book a Teams meeting with one of our Project Managers here:

https://www.sesameaccess.com/book-a-meeting